The LaserLinc Ecosystem Powered by Total Vu™ HMI

Unify every part of your extrusion process under one intelligent platform

Why Disconnected Systems Fail

When measurement and inspection systems are disconnected, quality decisions are made too late. Scrap increases, startups slow production, and process issues go unnoticed until they become costly.

The Ecosystem as Your Solution

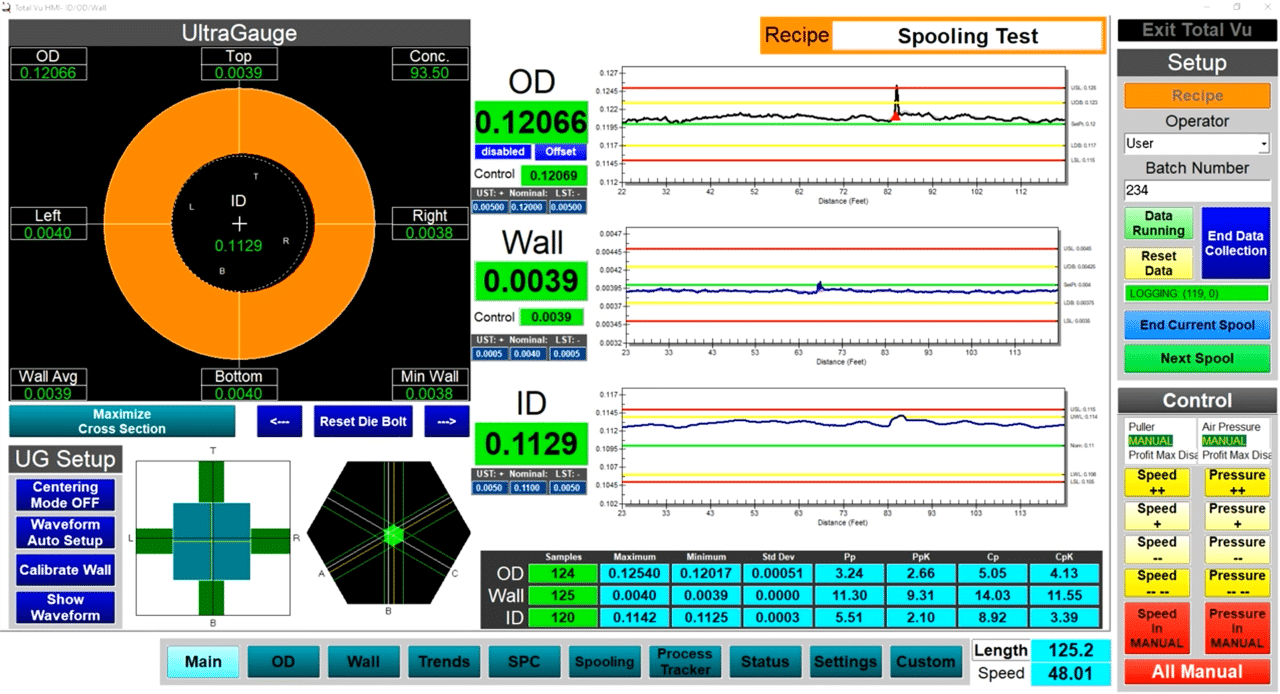

Instead of managing multiple interfaces, independent setups, and inconsistent reporting, everything is united under Total Vu™ HMI. Operators get clear guidance. Engineers get reliable insight. Management gets measurable consistency.

| Traditional Approach | LaserLinc Ecosystem |

|---|---|

| Multiple systems with separate interfaces | Unified through Total Vu™ HMI |

| Manual coordination & checks | Recipe-based process logic |

| Data is isolated per device | Synchronized across measurement tools |

| Late defect or profile detection | In-process evaluation and feedback |

| Extended startup relying on operator | Guided setup with process alignment |

What “Unified” Delivers

- ✔ Less time training operators

- ✔ Less troubleshooting

- ✔ Faster validation after a tool change

- ✔ Fewer late-stage quality issues

- ✔ Fewer dependencies on “expert users”

“As your line evolves — new features, tighter tolerances, higher speeds — the ecosystem grows with it. Measurement logic, recipe control, and analysis adapt without needing new hardware platforms.”

The products that create our Ecosystem

Total Vu™ HMI

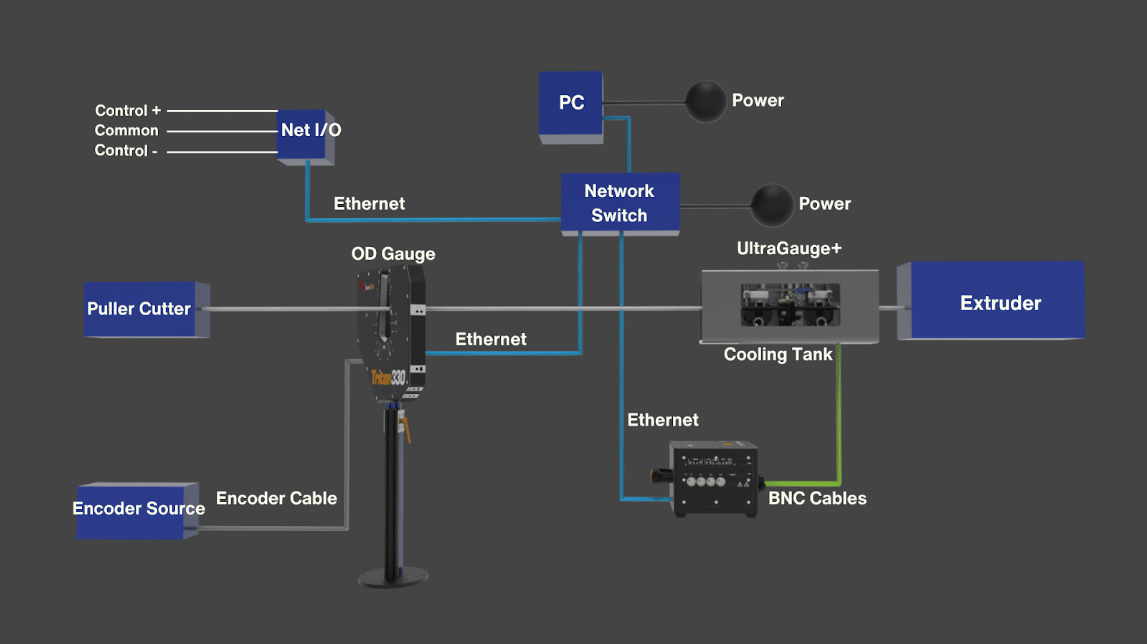

This is where LaserLinc started! Total Vu™ HMI was the first product created by LaserLinc, from the beginning we knew an ecosystem encompassing even our competitors equipment would be beneficial to the industry. Total Vu™ HMI allows you to connect micrometers, ultrasonic, PLCs, and other analog or digital devices from all sorts of manufactures under our HMI. Creating a singular source for all that data and control.

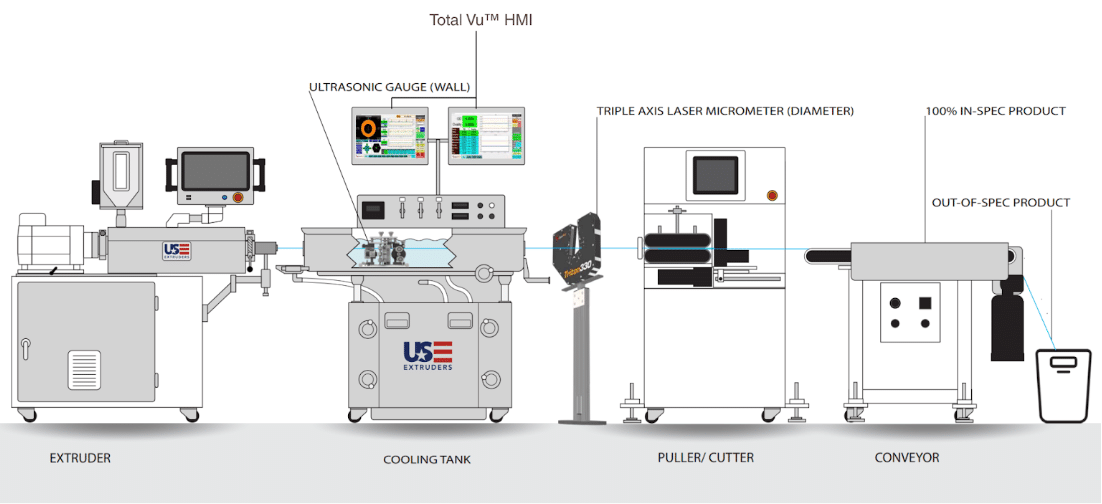

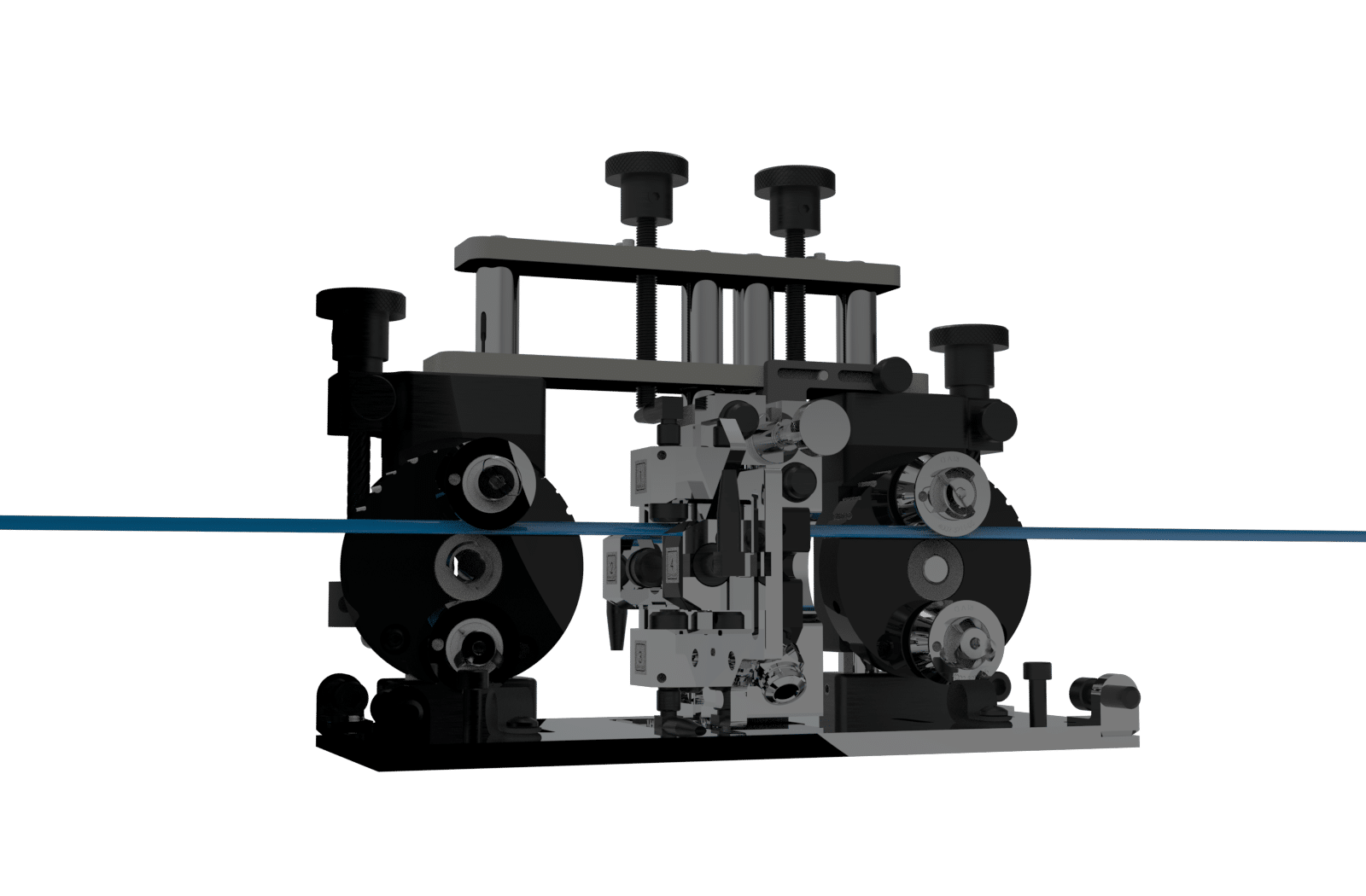

Laser Micrometers

The LaserLinc line of Laser Micrometers offers 1, 2, or 3 axes of coverage with scan rates from 300 to 18,000 scans per second. We can accommodate product sizes from 0.015mm - 231mm (0.0006" - 9.1"). These products provide diameter, ovality, and flaw detection

UltraGauge+

Ultrasonic measurement provides wall thickness and concentricity for your tubing products. These measurements are synced with the Laser Micrometer measurements and encoder feedback to provide Outer and Inner Diameter with a length stamp on each measurement so you can track flaws in the production without needing a respooler. Metals, Alloys, Plastics, Rubbers and many other materials can be measured with our UltraGauge+ product line. This includes tradionally difficult to measure materials such as Nitinol.

Why It Matters

Manufacturers rely on multiple measurement and inspection systems to maintain quality. But when those systems operate independently, critical information is delayed or lost between processes. Startups take longer, dimensional shifts and defects go unnoticed until late in production, and troubleshooting depends heavily on operator interpretation.

The LaserLinc ecosystem solves this by bringing all measurement points together into one platform — Total Vu™ HMI. Each tool still performs its function, but the entire process is now analyzed and understood as a single continuous operation.