LaserLinc’s UltraGauge+™ Series Revolutionizes In-Process Measurement for High-Specification Product

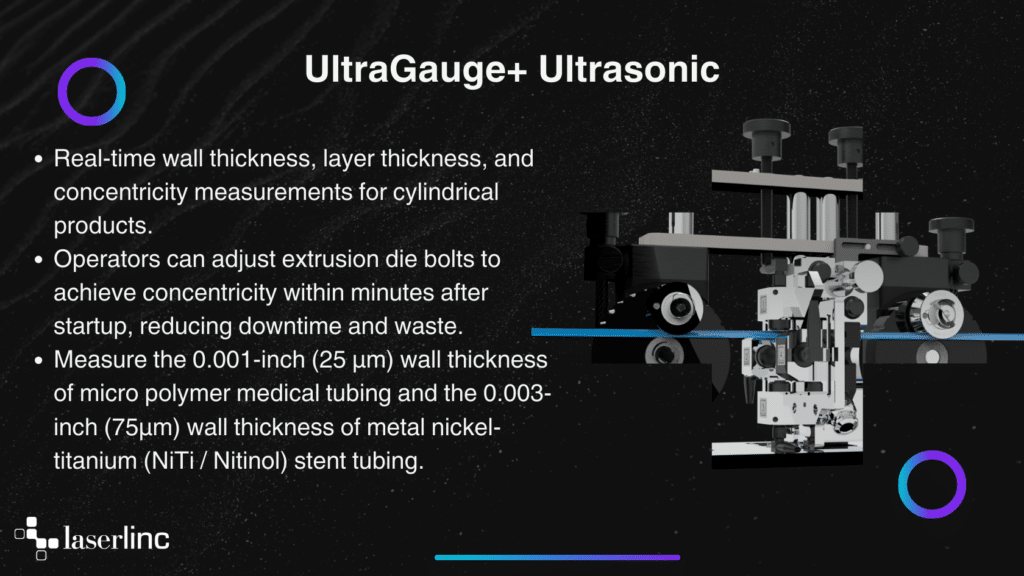

Dayton, OH – LaserLinc, the leader in open, scalable measurement and control solutions that adapt to the way you work, is proud to introduce its UltraGauge+™ series. This innovative product line of ultrasonic gauges offers accurate, real-time measurements of wall thickness, layer thickness, and concentricity for cylindrical products such as plastic, rubber, glass, metal tubing, insulated wire and cable, and certain multi-layer products.

“We understand that every production process is different, and we’re committed to providing solutions that meet our customers’ specific needs,” said President Jeff Kohler, LaserLinc. “Our UltraGauge+ series is designed to provide precise, real-time measurements that help our customers easily achieve their production goals. And our ability to manufacture custom configurations for the UltraGauge+ series is just one example of how we work to provide the best possible tools for our customers.”

LaserLinc’s UltraGauge+ series can be tailored to fit specific product types, production environments, and other unique needs. It is commonly installed on an extrusion production line for continuous in-process measurement. With precise real-time wall and concentricity measurement, operators can adjust extrusion die bolts to achieve concentricity within minutes after startup, reducing downtime and waste.

One of the greatest benefits of LaserLinc’s UltraGauge+ technology is its thin-wall measurement capability. The device can measure the 0.001-inch (25 μm) wall thickness of micro polymer medical tubing and the 0.003-inch (75μm) wall thickness of metal nickel-titanium (NiTi / Nitinol) stent tubing.

LaserLinc’s UltraGauge+ devices can also be paired with LaserLinc’s laser micrometers for outside diameter measurement, providing an inside diameter measurement for tube, hose, and pipe. This combination of technologies enables operators to make precise, in-process measurements, reducing material usage, improved product quality, and shorter startup cycles.

LaserLinc’s UltraGauge+ product line includes a wide range of sensor assemblies and accessories to support a variety of production processes and locations, making it a versatile solution for high-specification product manufacturers. The UltraGauge+ series can be used with LaserLinc’s Total Vu HMI for process visualization, data logging, reporting, SPC, tolerance checking, and more.

For more information about LaserLinc’s UltraGauge+ series, please visit: https://www.laserlinc.com/products/ultragauge.