Brochures/Product Sheets/Data Sheets

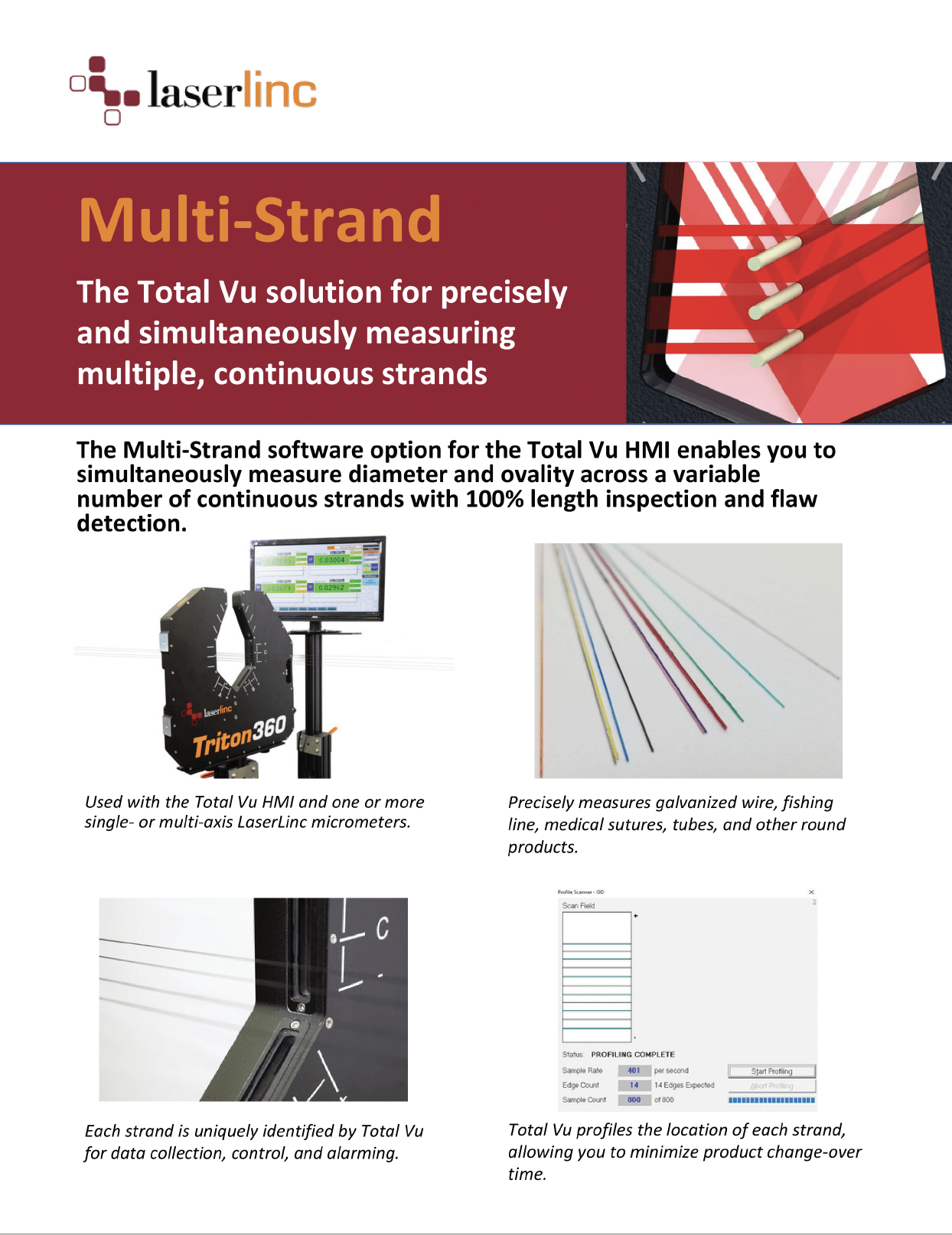

Multi-Strand

The Multi-Strand software option for the Total Vu HMI enables you to simultaneously measure diameter and ovality across a variable number of continuous strands with 100% length inspection and flaw detection.

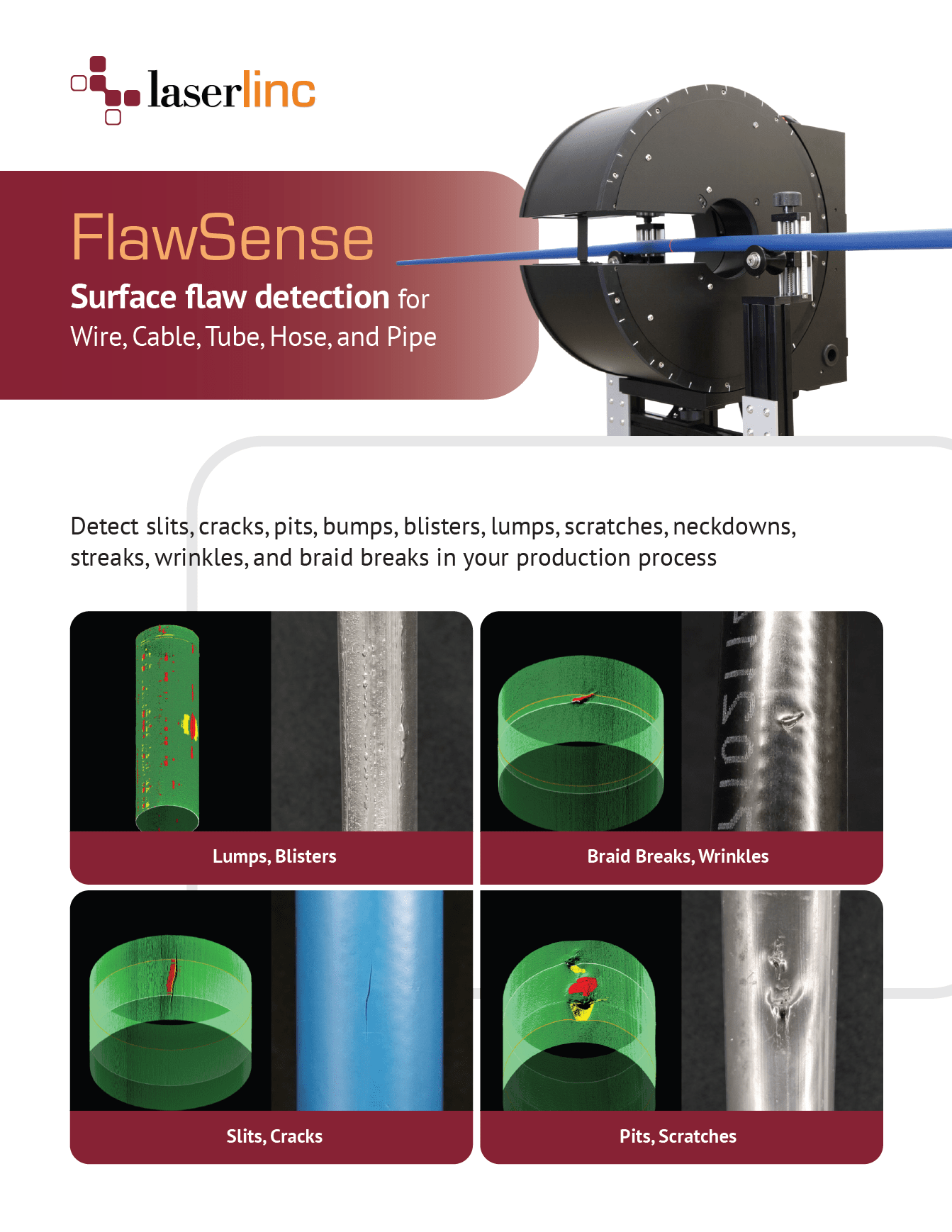

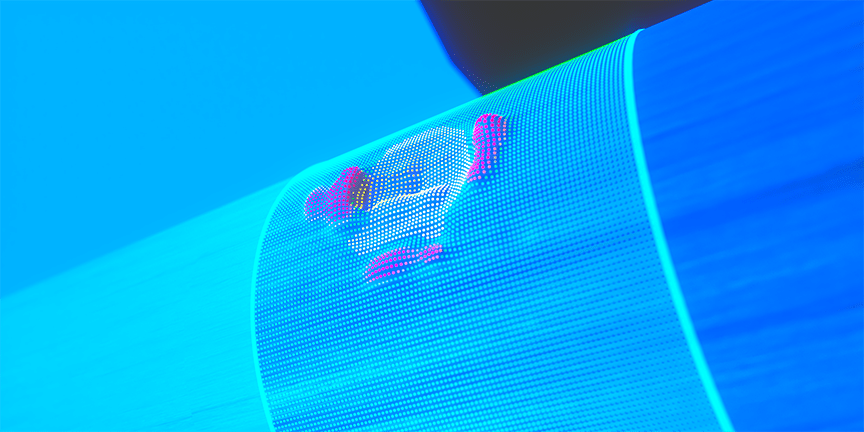

FlawSense - Surface flaw detection

Detect slits, cracks, pits, bumps, blisters, lumps, scratches, neckdowns, streaks, wrinkles, and braid breaks in your production process while using 360° orientation-independent flaw detection.

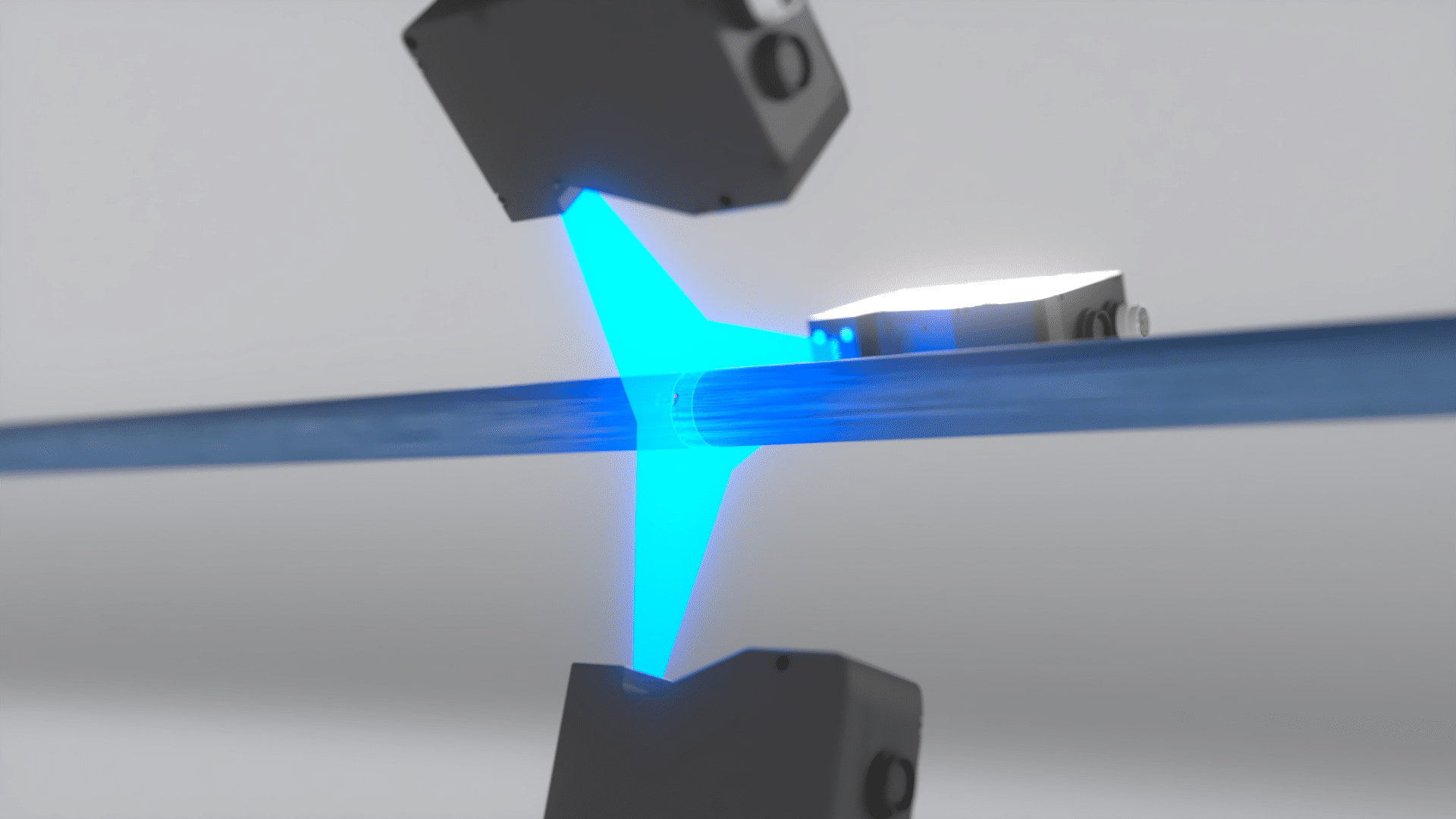

METRON AUTOMATED INSPECTION

Complete, accurate dimensional inspection with rapid data collection and tolerance verification. Ideal for catheters, guidewires, medical tubes, and other cylindrical products.

PROCESS VISUALIZATION BEYOND MEASUREMENT

Using laser and ultrasonic-based technologies, LaserLinc helps you solve your in-process and off-line non-contact measurement and process visualization needs through innovative products, software expertise, and deep application knowledge.

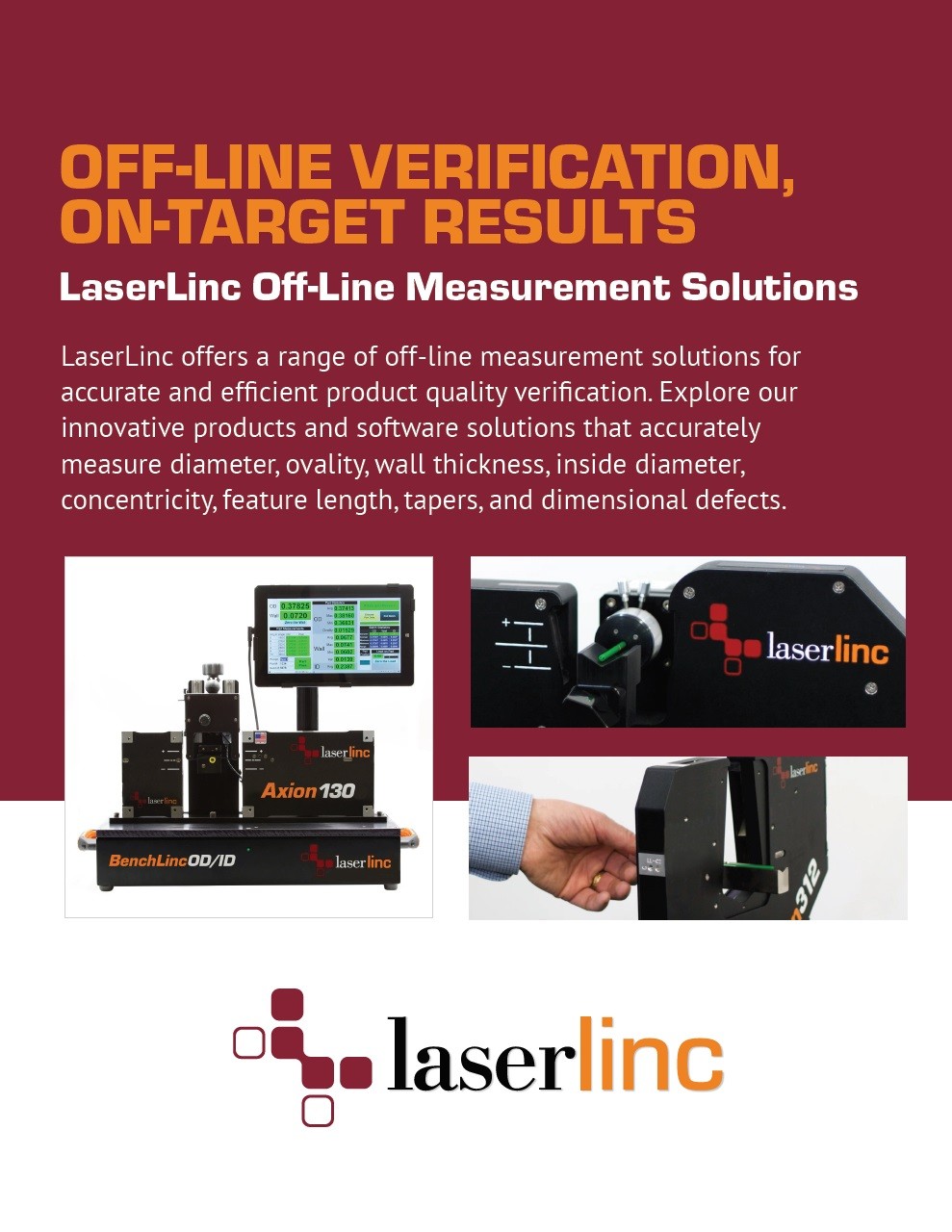

OFF-LINE VERIFICATION, ON-TARGET RESULTS

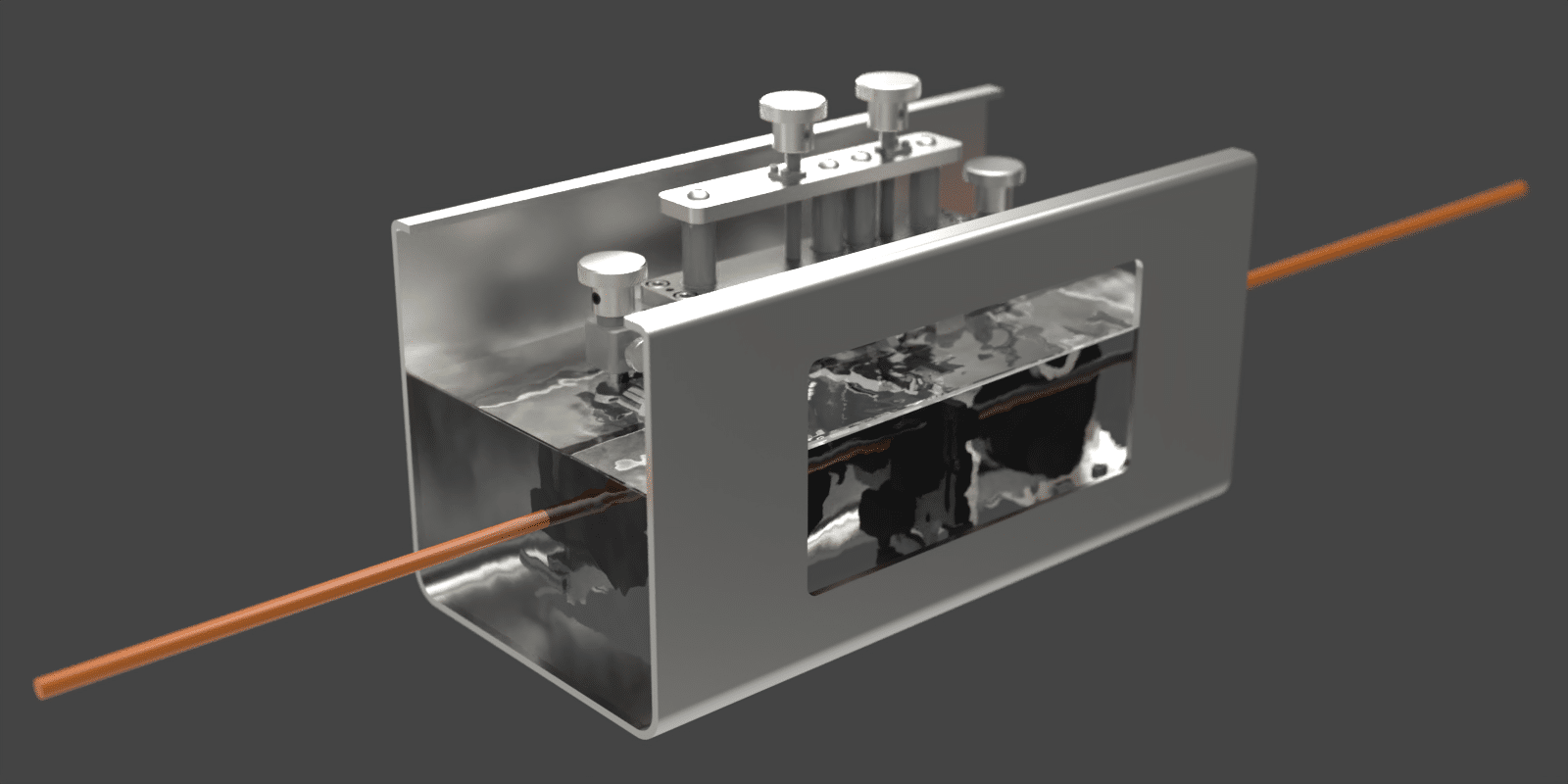

LaserLinc offers a range of off-line measurement solutions for accurate and efficient product quality verification. Explore our innovative products and software solutions that accurately measure diameter, ovality, wall thickness, inside diameter, concentricity, feature length, tapers, and dimensional defects.

Micrometer Data Sheet

FlawSense featured in Wire & Cable Technology International

LaserLinc announces its new high-speed, online inspection and measurement system, FlawSense. It’s ideal for manufacturers of high-specification tube, pipe and wire and cable.

UltraGauge+ Data Sheet

Case Studies/Customer Stories

Automating Surface Flaw Detection

Delivers Significant Value

Industrial Hose Manufacturer Automates Surface Flaw Detection and Realizes Significant Value.

The company required a system to deliver accuracy better than + /-0.001 in. LaserLinc’s FlawSense surface defect detection system automated their process, delivered process efficiency, and improved product quality.

AUTOMATING DIMENSIONAL INSPECTION DRIVES CONSIDERABLE EFFICIENCES

Leading Medical Device Manufacturer Automates the Dimensional Inspection of Catheters and Realizes Significant Efficiences.

The company needed accurate, repeatable, and reliable dimensional inspection at multiple locations on a variety of catheters. LaserLinc's Metron system offered an automated inspection solution that enhanced measurement capabilities for R&D, improved productivity, and delivered a reliable solution for production.

Videos

Webinars

Production Under Pressure: Why Vision and Manual Inspection Are Failing You

Join us for a deep dive into a new technology that provides 100% dimensional surface inspection of tubes, wires, cables, and more – using laser-line triangulation. Discover why leading manufacturers are abandoning manual inspection and underperforming vision systems in favor of this highly precise, fully automated solution.

FlawSence Surface Defect Detection

This webinar offers valuable insights into LaserLinc's FlawSense technology, a real-time, 3-dimensional laser line triangulation defect detection system. Learn about its functionality, turnkey solutions, competitive advantages, and more.

White Papers

Closing the Loop Between In-process and Offline Measurements of Flexible Medical Tubing Products for Compliance Validation

Demand for medical device consumables, such as tubing, is increasing, creating production challenges for manufacturers. One critical challenge is how to accurately measure flexible products for compliance validation without sacrificing production speeds.

WHAT'S YOUR CHALLENGE?

Contact us to learn more about how LaserLinc solutions can help you meet your measurement and quality objectives.