FlawSense

Dimensional Defect Detection

The most reliable defect detection solution on the market.

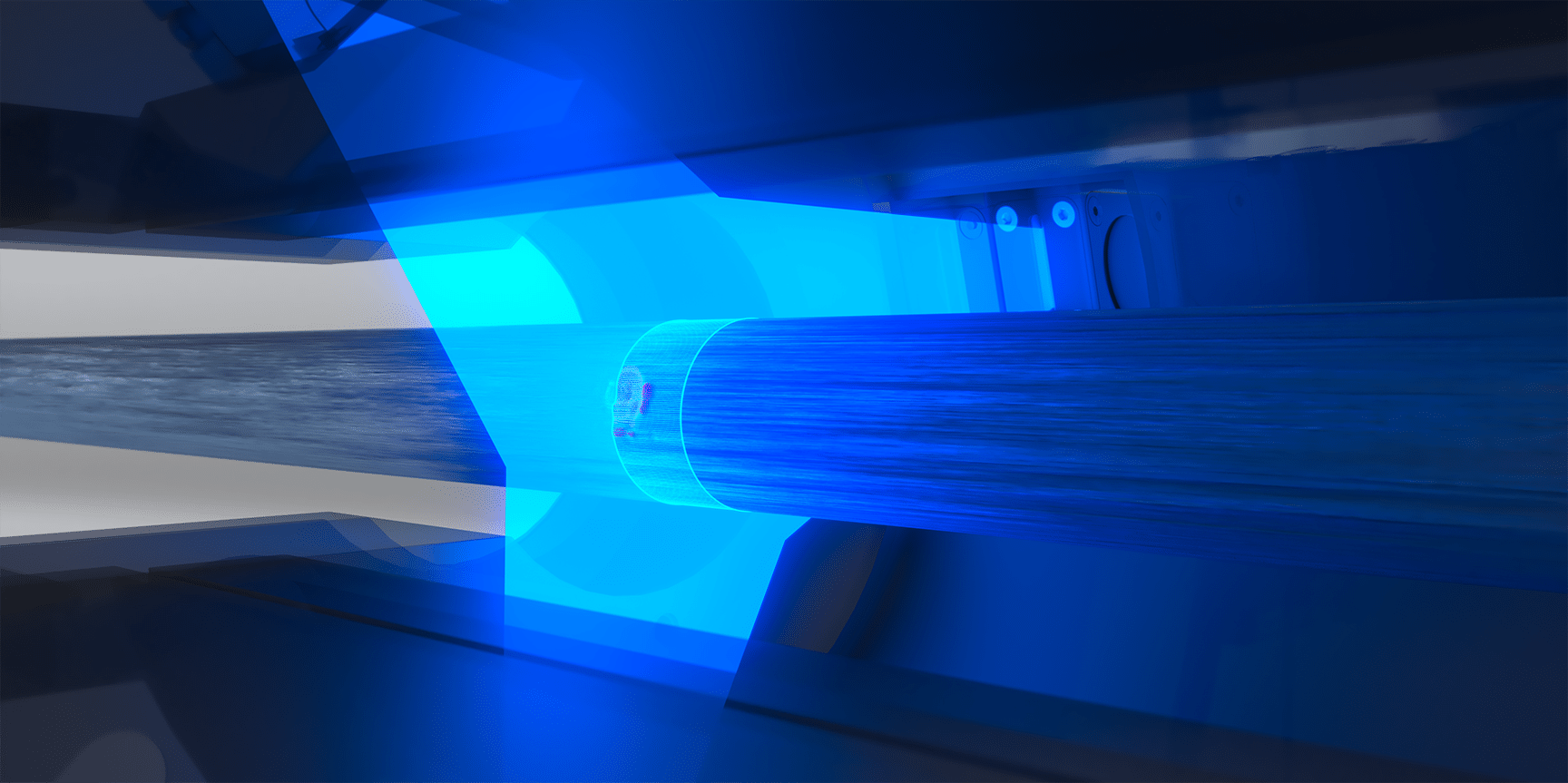

FlawSense™ technology is the first-of-its-kind defect detection tool that uses laser-line triangulation to measure diameter and ovality, providing a contour map at speeds up to 10,000 times per second and nearly 100% inspection coverage. It accurately measures the outer diameter, evaluates ovality, and identifies defects using a true 360-degree view.

The FlawSense systems are designed, manufactured, and assembled in the US.

Automating Surface Quality Inspection

Superior Measurement Technology

Laser-line triangulation technology offers the most advanced solution for real-time 3D inspection. With its precise dimensional measurement capabilities, this technology enables us to achieve a more comprehensive and accurate three-dimensional scan, delivering up to 50x more precision than a traditional vision system.

Set up defect detection criteria in minutes

The advanced proprietary algorithms and point cloud data manipulation enable detailed contour computation. The system's high resolution and frame rate reliably detect even the smallest defects that other systems cannot.

Adaptive Solutions

LaserLinc offers versatile continuous inspection, re-spool inspection, part sorting, and off-line solutions with Total Vu™ HMI and FlawSense™ technology.

Find the Right Solution

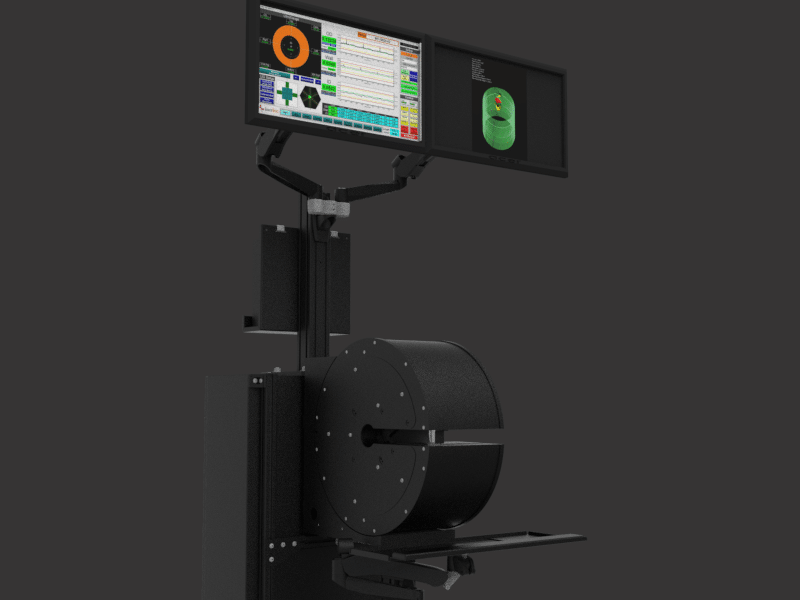

On-line Mobile Solution

This mobile system is equipped with casters, making moving it to any desired location effortless.

On-line Modular Solution

This bolt-to-the-floor system provides a secure and stable foundation for long-term dedicated use.

Off-line with FlawSense Metron™

Renowned for its precision, FlawSense Metron Technology is ideal for inspecting parts under 72 inches long, such as catheters or medical tubes with variable diameters and tapers. Its User-friendly controls allow operators to easily mount and inspect each part from the batch, ensuring the product meets specifications while identifying any surface defects.

FlawSense technology is not a vision system.

It's something better.

LaserLinc’s FlawSense technology provides a 3D measurement and defect detection solution using laser-line triangulation, unlike traditional 2D camera-based vision systems. It does not rely on color or visual patterns but measures and analyzes 360° of the surface contour in precise detail to detect and report defects at production speeds.

Hear From A FlawSense Customer

Microspec CEO, Tim Steele, discusses the various advantages of FlawSense technology. He highlights how it stacks up against other defect detection systems and solutions, explains his reasons for choosing FlawSense over competing options, and covers additional insights.

The Many Costs of a Defect

Watch the Webinar

Defects can cause financial losses and harm your reputation, affecting productivity and leading to rejected products. In industries like healthcare, catching defects early is crucial. The FlawSense solution helps you avoid the negative impacts of defects, ensuring you maintain your high-quality standards. Watch the short animation to see how FlawSense systems work.

In this webinar, FlawSense Product Manager Chad Walker shares insights into how FlawSense technology surpasses other defect detection solutions, explains its functionality, and highlights the key benefits of integrating FlawSense systems into your operations.

Get the most out of your setup with Total Vu HMI & Flaw Viewer

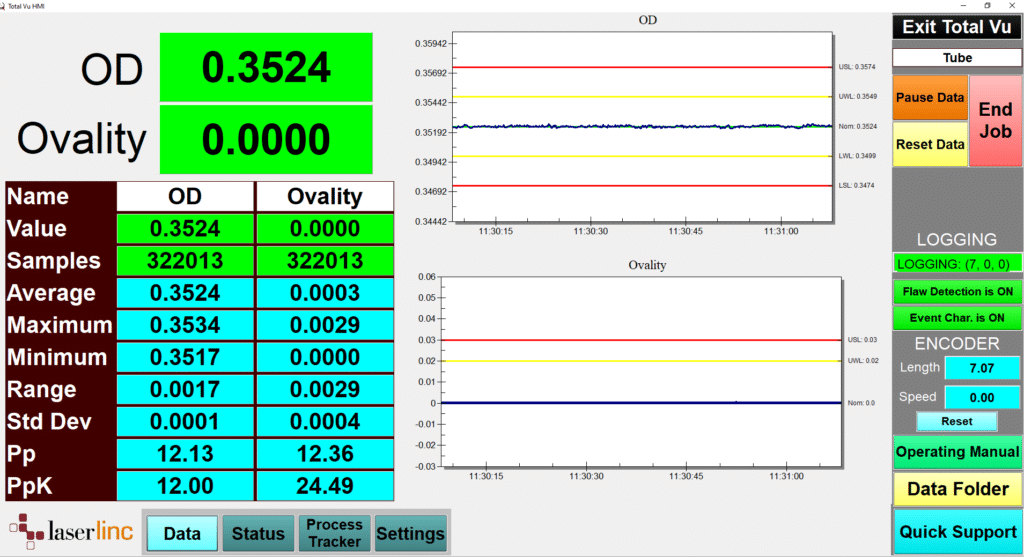

The Total Vu HMI from LaserLinc is a comprehensive data acquisition platform for wire and cable production processes. It provides real-time information and enables manufacturers to aggregate, visualize, and analyze data from multiple sources.

Total Vu HMI provides:

• Access to data from anywhere in your facility with OPC UA

• Statistical process control (SPC) for insight into your process

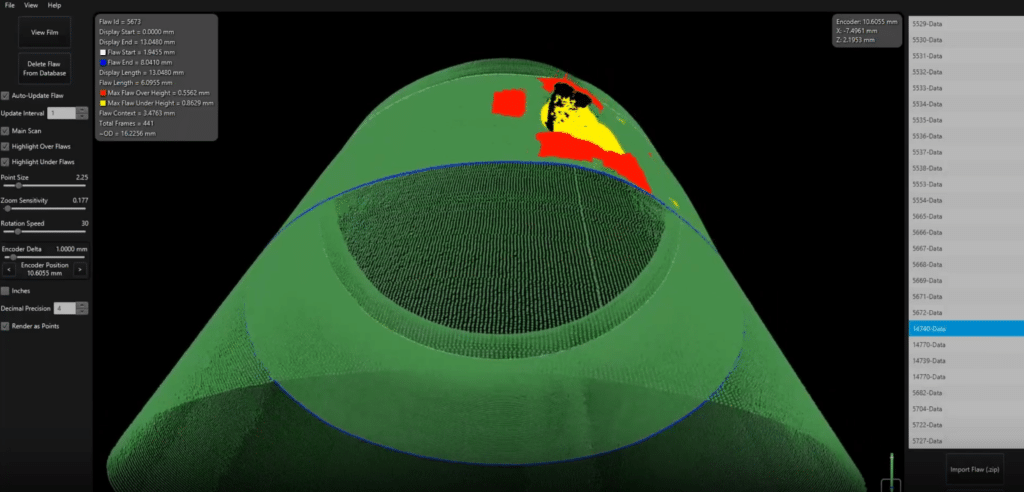

With Flaw Viewer, you can monitor product scans and detect defects in real time through a visualized 3D user interface. Allowing you to closely examine the parts, view defects in detail, and make informed decisions about which parts to reject or keep.