Laser Profile Measurement

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.

ETHERNET INTERFACE

These products use a standard Ethernet connection to transfer data between the device and the host processor.

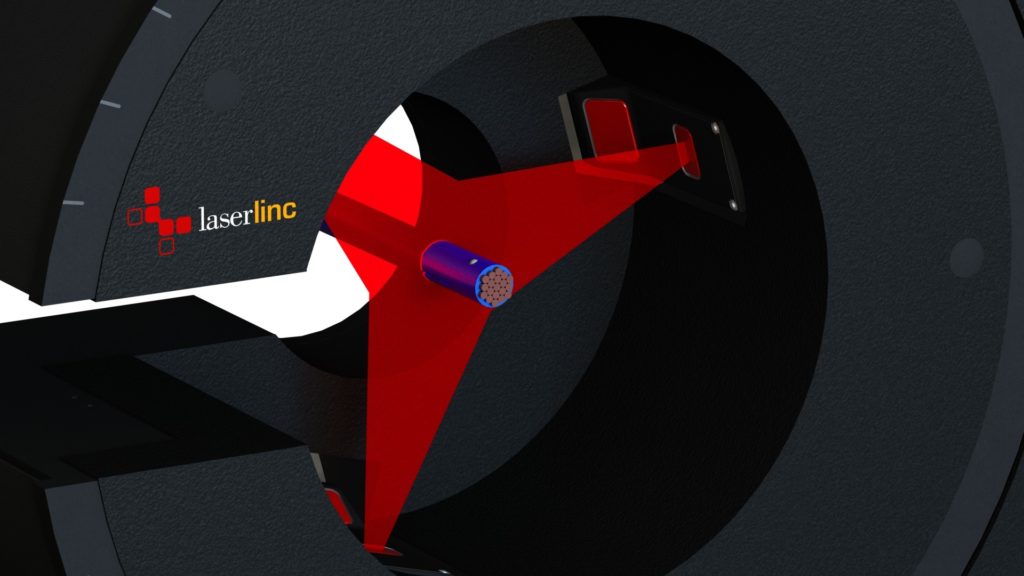

FlawSense 360 ° Surface Defect Detection

Unveiling FlawSense Technology

This webinar offers valuable insights into LaserLinc's FlawSense technology, a real-time, 3-dimensional laser line triangulation defect detection system. Learn about its functionality, turnkey solutions, competitive advantages, and more.

Experience FlawSense demensional inspection technology

Get an inside look at FlawSense. Say goodbye to unreliable vision systems, laser micrometers, lump-neckdown detectors, and manual inspection.

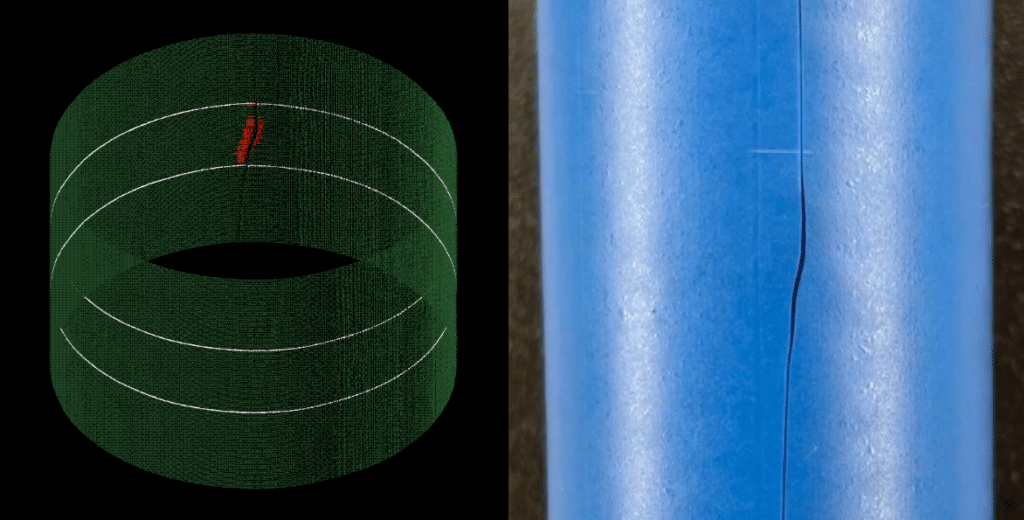

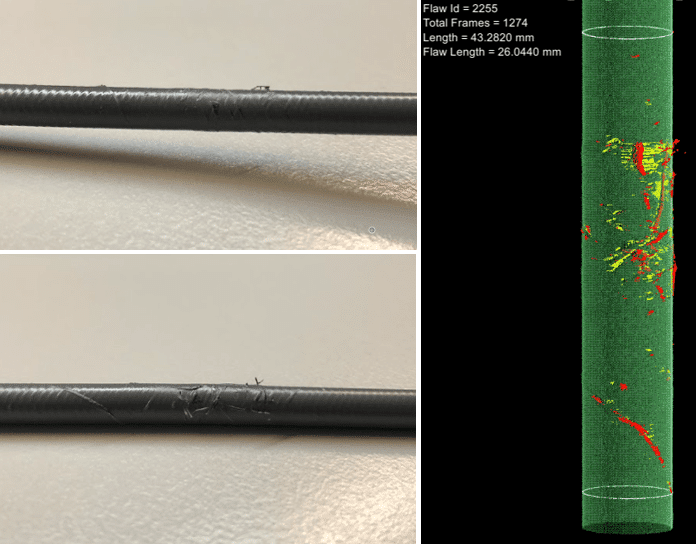

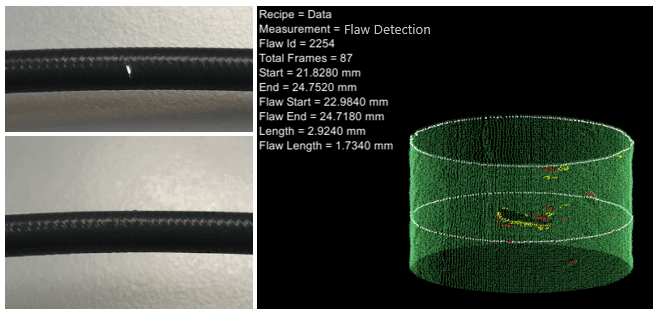

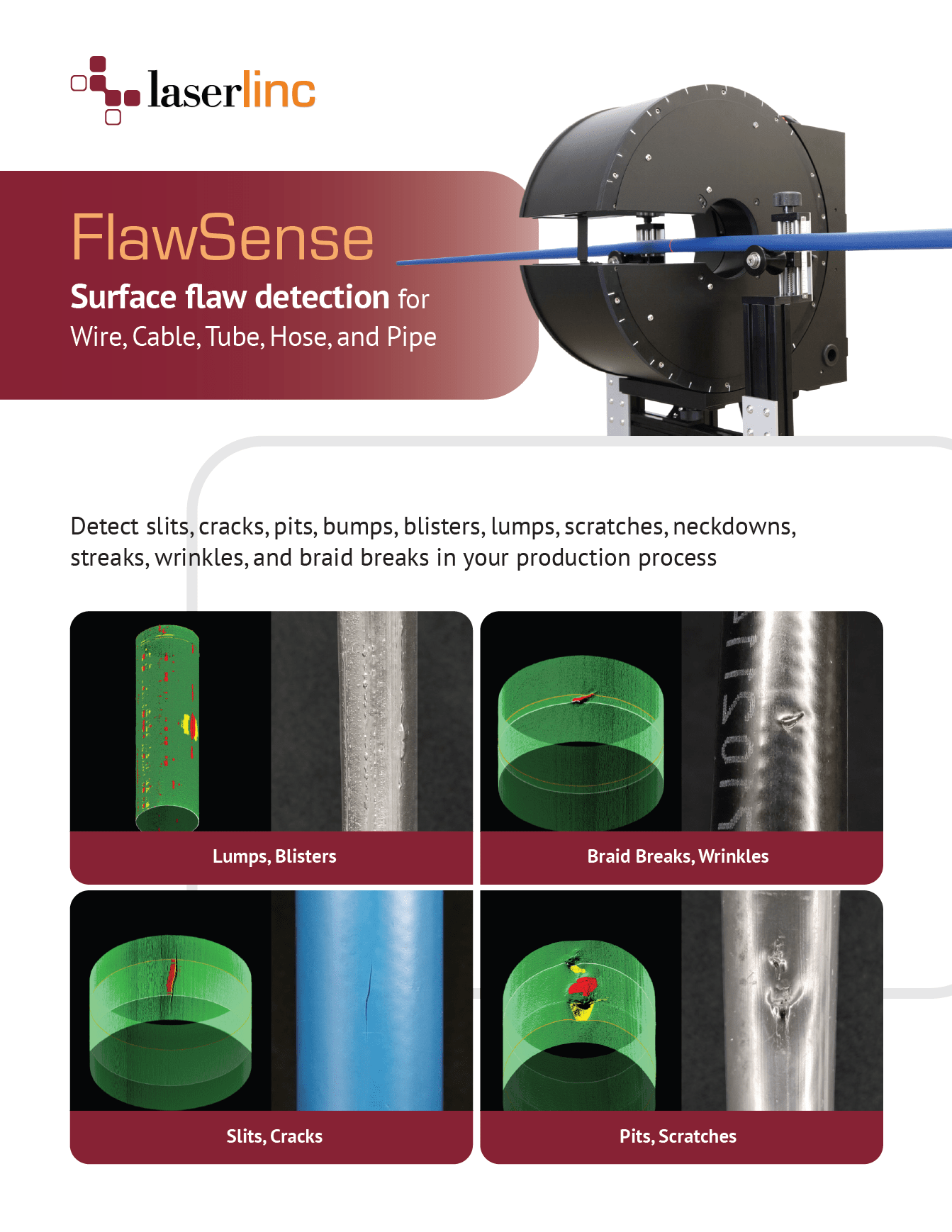

FlawSense - Surface flaw detection

Detect slits, cracks, pits, bumps, blisters, lumps, scratches, neckdowns, streaks, wrinkles, and braid breaks in your production process while using 360° orientation-independent flaw detection.

Automating Surface Flaw Detection

Delivers Significant Value

Industrial Hose Manufacturer Automates Surface Flaw Detection and Realizes Significant Value.

The company required a system to deliver accuracy better than + /-0.001 in. LaserLinc’s FlawSense surface defect detection system automated their process, delivered process efficiency, and improved product quality.

FlawSense featured in Wire & Cable Technology International

LaserLinc announces its new high-speed, online inspection and measurement system, FlawSense. It’s ideal for manufacturers of high-specification tube, pipe and wire and cable.

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.

ETHERNET INTERFACE

These products use a standard Ethernet connection to transfer data between the device and the host processor.