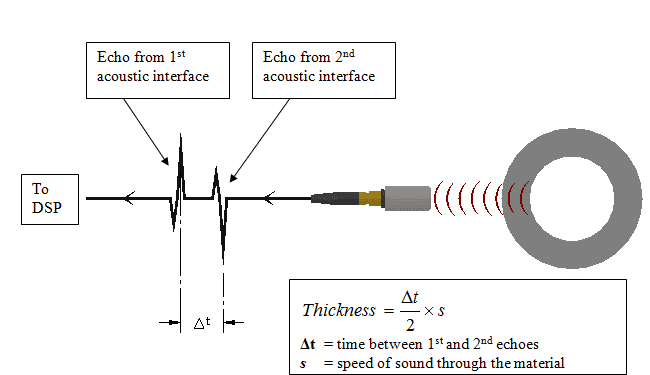

Ultrasonic Wall Thickness Measurement

4 YEAR WARRANTY

We’re so confident in our products that with the exception of a few select components we guarantee every part we manufacture with an industry-leading four-year warranty.

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.

ETHERNET INTERFACE

These products use a standard Ethernet connection to transfer data between the device and the host processor.

Ultrasonic Wall Thickness Measurement

4 YEAR WARRANTY

We’re so confident in our products that with the exception of a few select components we guarantee every part we manufacture with an industry-leading four-year warranty.

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.

ETHERNET INTERFACE

These products use a standard Ethernet connection to transfer data between the device and the host processor.