LASER MICROMETERS

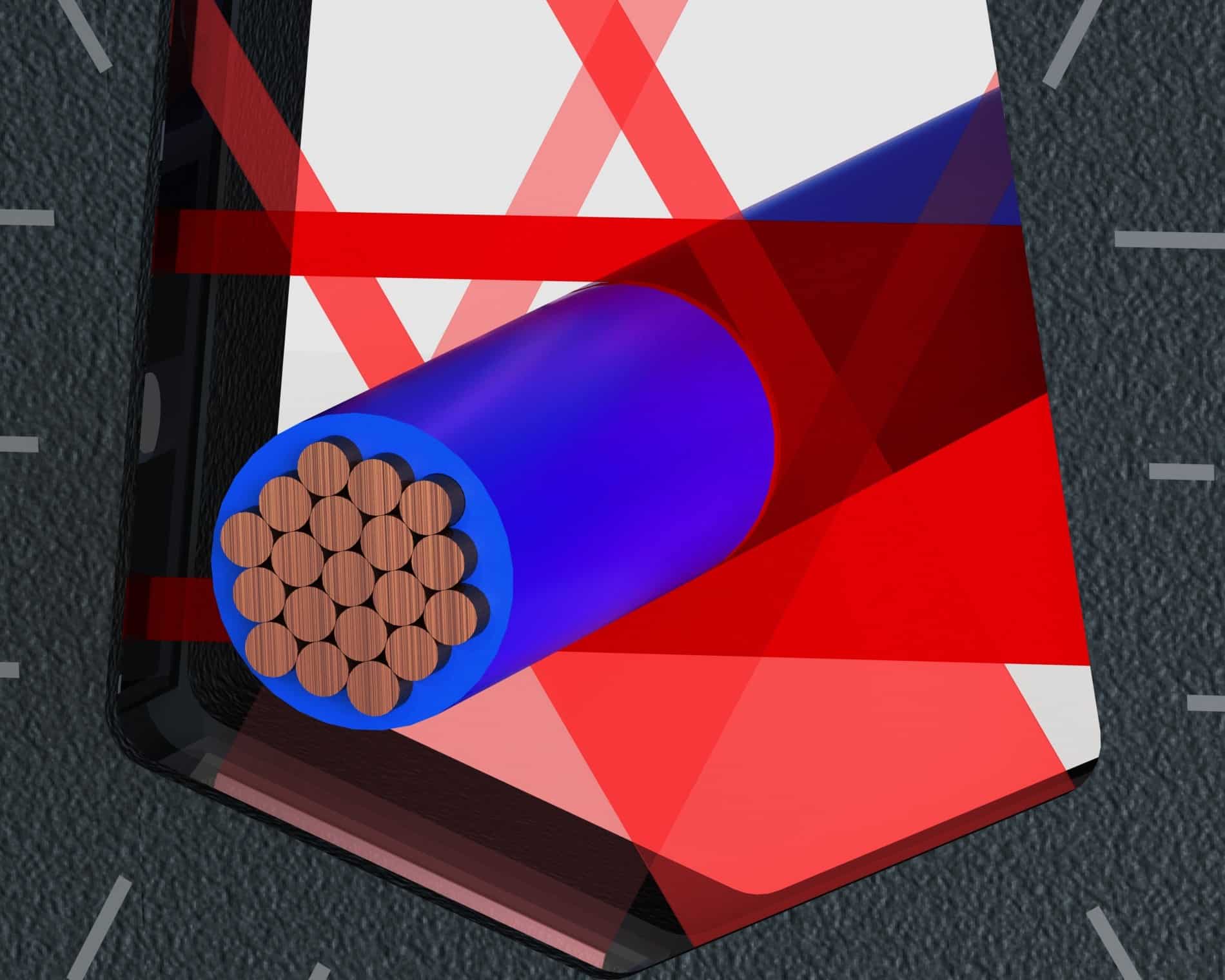

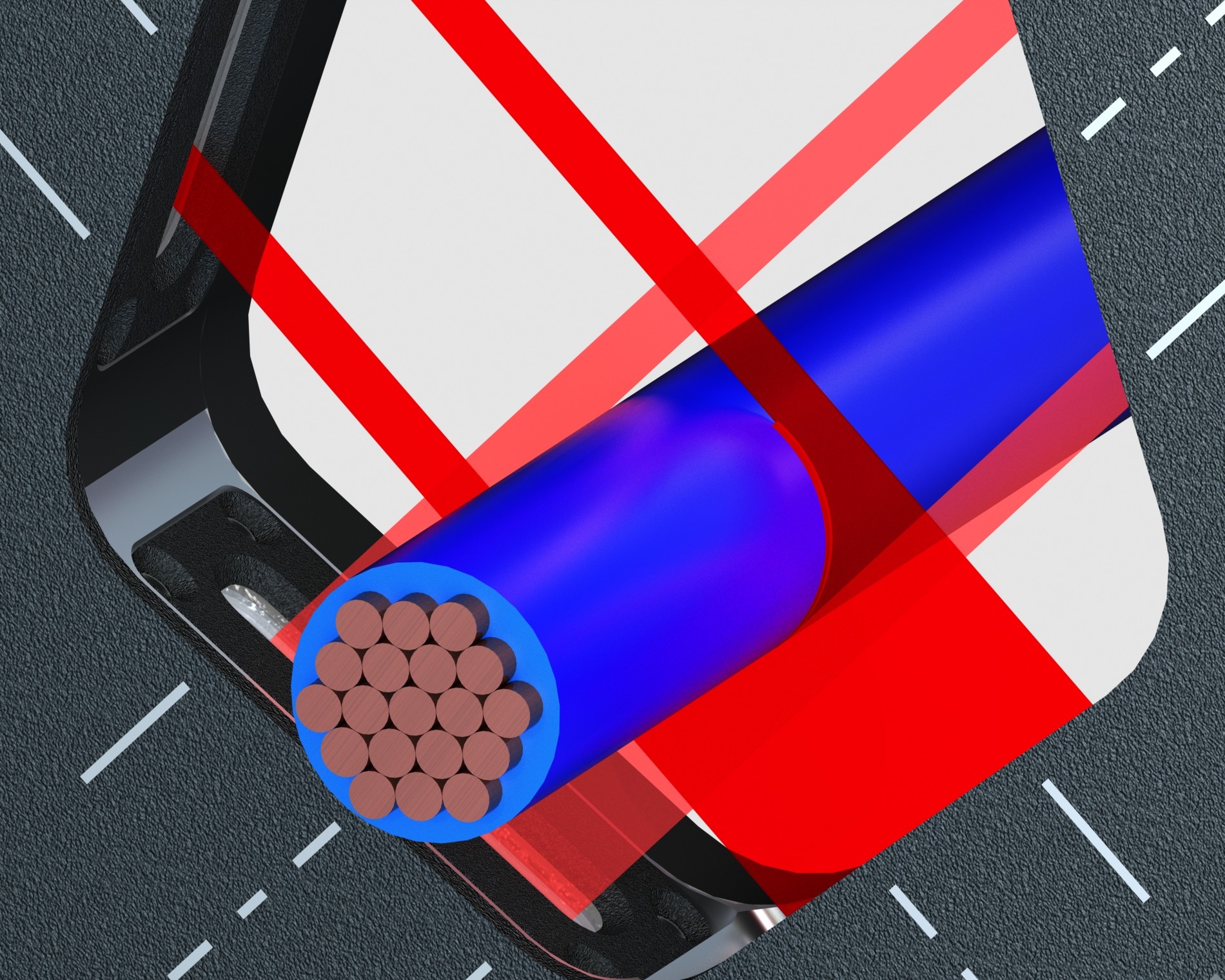

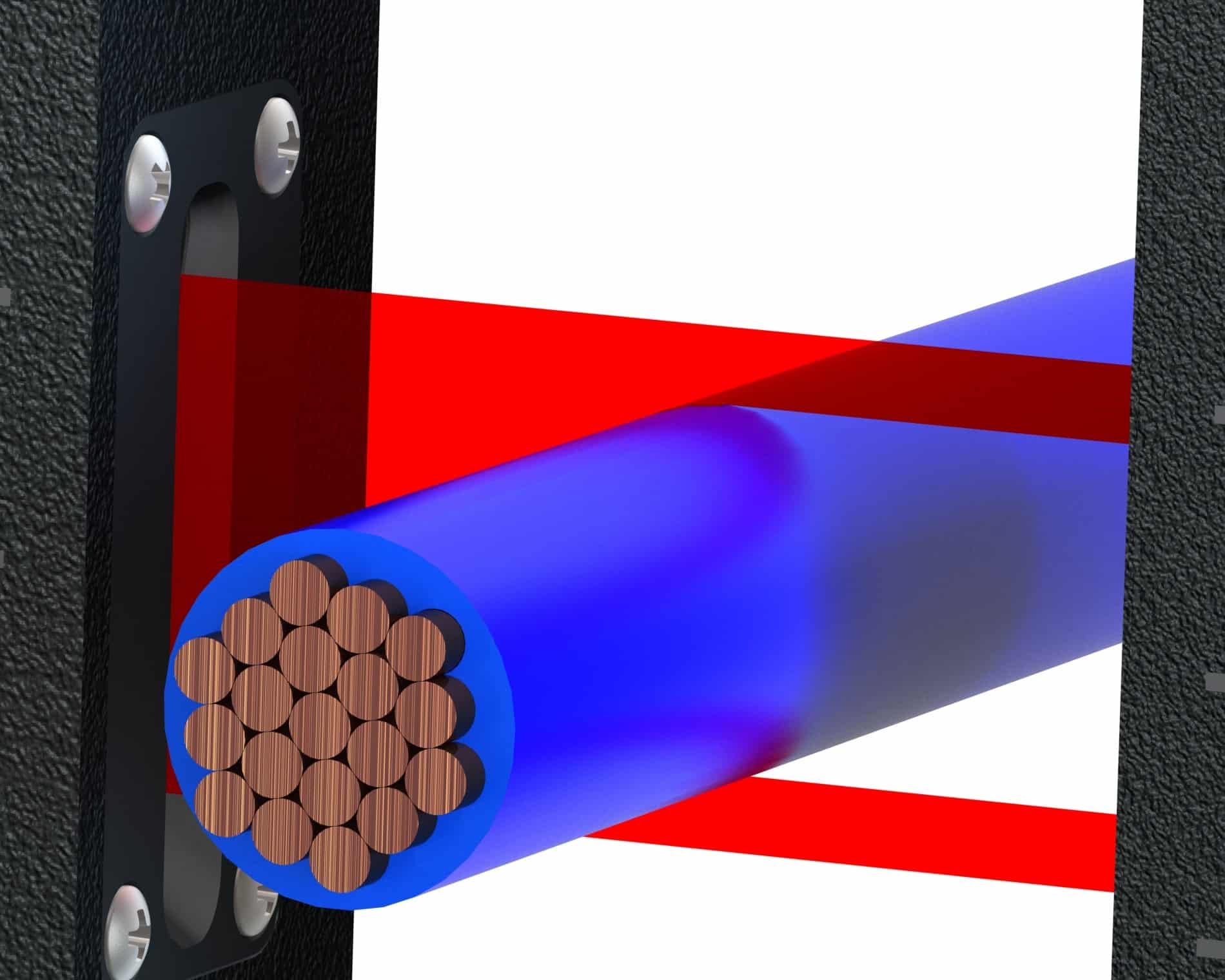

LaserLinc understands how critical your in-process and off-line measurements are. Our laser micrometers are ideal for measuring outside diameter, ovality, wall thickness, concentricity, profile and more.

Selecting the Best Laser Micrometer

Some key questions that must be answered in order to select the best micrometer for your application:

- What is the shape or profile of the product: round, rectangular, hexagonal, or other?

- What are the smallest and largest diameters (or dimensions) you need to measure?

- If your product is supposed to be round, do you need to know when it is not round?

- How often do you need to check the dimension(s)?

- What are the most stringent engineering tolerances on the products you are measuring?

Our triple-axis (also called triple-plane) laser micrometers measure products from three directions, precisely calculating product diameter, ovality, and position. These three axes of measurement are coplanar and separated by 60 degrees from each other, and the measurement field is perpendicular to the product.

Triton-series micrometers provide the best average diameter, ovality measurement regardless of product orientation, and are most capable of detecting defects.

Our dual-axis (also called dual-plane) laser micrometers measure products from two directions, precisely calculating product diameter, ovality, and position. These two axes of measurement are coplanar and perpendicular to each other, and the measurement field is perpendicular to the product.

Dual-axis micrometers provide a good average diameter, ovality measurement, and are capable of detecting defects which do not encircle the product.

Our single-axis laser micrometers measure product diameter and position from a single

direction. Single-axis measurement offers the most application and installation flexibility.

Single-axis micrometers have the most flexible mounting options and can also be used for measurements dual-axis and Triton micrometers cannot make.

LaserLinc offers a range of optional accessories to help you get the most out of your laser micrometers. These accessories simplify installation and use, optimize performance, and extend the operating life of your micrometer.

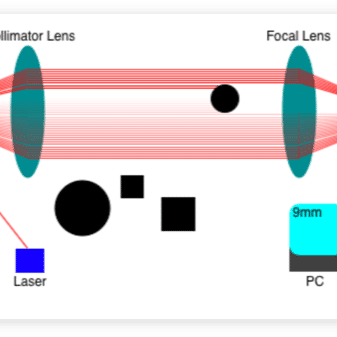

A scanning laser micrometer uses a rotating optical element to reflect or refract a laser beam through a measurement area and across the path of an object. The part obstructs the laser light, creating a shadow that persists for a time proportional to the size of the part.

The NetLinc™ interface uses a standard Ethernet connection to transfer micrometer data to the host processor. This seamless communication provides many advantages.