FlawSense™ Dimensional Detection Technology by LaserLinc

Setting New Standards Beyond Traditional Vision Systems, Laser Micrometers, and Manual Inspection.

LaserLinc, a leader in open and scalable measurement and process control solutions that adapt to the way you work, is set to showcase its cutting-edge FlawSense™ technology solutions at the 2024 and 2025 tradeshow circuit.

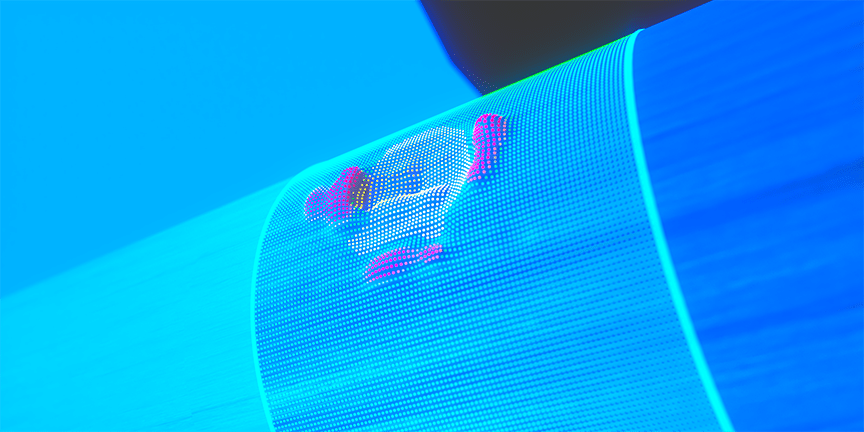

The first of its kind, FlawSense technology harnesses the power of laser-line triangulation, which delivers an unparalleled, true 360-degree three-dimensional inspection of products. In real-time, flawSense technology quickly identifies surface defects such as cracks, bumps, pits, wrinkles, and scratches. The system’s intelligence promptly relays defect size and location to operators during production, enabling the swift removal of flawed material. FlawSense technology also ensures the most precise diameter and ovality measurements, ensuring adherence to the highest product quality standards.

This technology solution stands out for its ease of use, adaptability, and accuracy compared to traditional 2-D camera-based vision systems and variable, labor-intensive manual inspection methods. Operators can efficiently detect defects, saving time and materials, regardless of product shape, orientation, or ambient light conditions. Moreover, FlawSense technology archives defect data for 3D playback and visualization, offering invaluable process insights for continuous improvement. FlawSense technology solutions are reliably up to 50 times more accurate than vision systems and laser micrometers.

The versatility of FlawSense extends across various applications, including subterranean and undersea fiber optic cables, complex armored cables, power cables, building wires, and tubing for critical cables, to name a few. Its customization capabilities allow operators to intuitively save measurement settings, facilitating future reuse and quick changeovers to streamline the inspection process, making it the preferred solution for industries emphasizing efficiency, consistency, and accuracy.

To learn more about FlawSense technology and LaserLinc’s comprehensive suite of solutions, visit www.laserlinc.com.