Precision Without Compromise: Real-Time Ultrasonic Measurement for Medical Tubing

In medical device manufacturing, particularly in catheter and tubing production, precision is not a luxury; it’s a regulatory and performance necessity. Wall thickness and concentricity directly impact flow rates in the tube, flexibility, durability, and patient safety. Yet many manufacturers still rely on intermittent, offline inspection methods that leave blind spots in quality control and introduce unnecessary risk.

Enter real-time ultrasonic measurement, a modern solution for today’s most demanding medical extrusion lines.

The Hidden Costs of “Close Enough”

Most quality teams in the tubing space have, at some point, encountered the limitations of handheld micrometers or vision-based systems. These tools often miss subtle eccentricity or, can’t measure internal wall structures, and require line stoppages or product removal for analysis.

The result?

- Longer startup times

- Lack of compliance

- Material waste

- Missed defects that are only caught downstream, or worse, in the field

- Manual interventions that reduce throughput and introduce variability

As wall thickness requirements shrink and performance expectations rise, traditional methods simply aren’t enough.

Real-Time Ultrasonics: A Smarter Approach

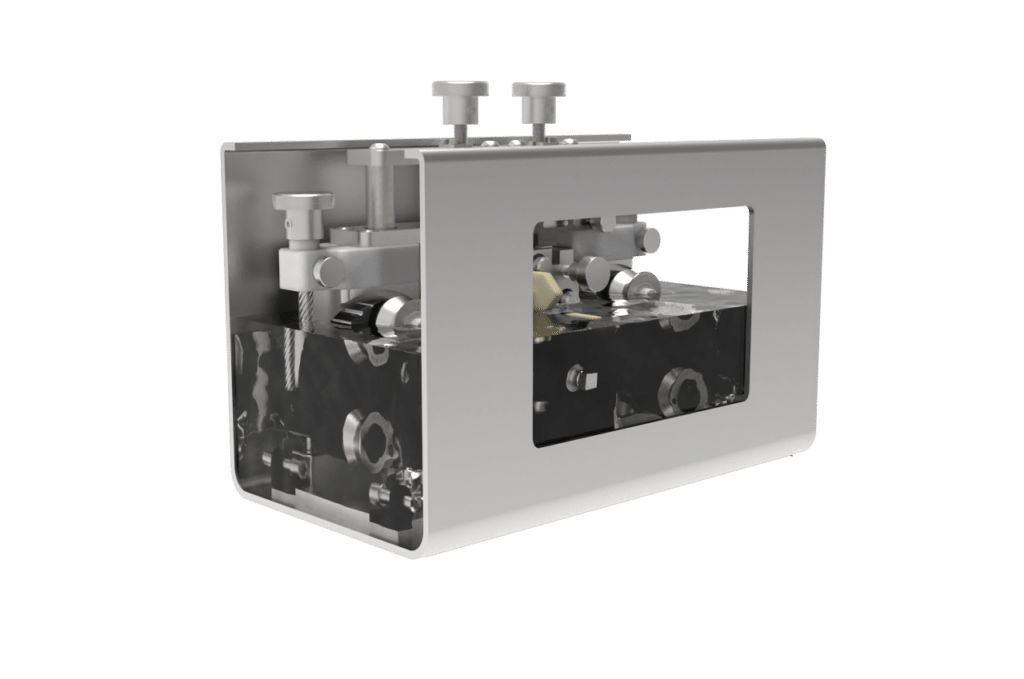

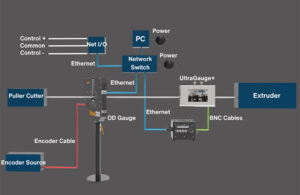

[Image courtesy of LaserLinc]LaserLinc’s UltraGauge+ system offers a better way forward. Using non-contact ultrasonic transducers mounted inline, UltraGauge+ ultrasonic solutions continuously monitor critical dimensions, wall thickness, inner diameter, outer diameter, ovality, and concentricity, as tubing is produced.

Instead of reacting to problems hours later, manufacturers gain instant visibility into every change, deviation, or drift as it happens.

Key capabilities include:

- Detecting walls as thin as 0.001” (25 µm)

- Monitoring concentricity and eccentricity in real time

- Supporting measurement of polymers, composites, and even metal tubing

- Seamless integration into existing extrusion lines

- Enabling closed-loop feedback to control air/vacuum pressure, extrusion screw RPM, or line speed

Real-World Impact: Efficiency and Compliance

For manufacturers producing cardiovascular catheters, implantable tubing, or precision sheaths, UltraGauge+ gauges help solve two problems at once:

1. Reducing scrap and downtime: Instead of manually dialing in wall thickness and wasting valuable material, teams can tune the process in minutes with real-time feedback.

2. Documenting compliance with confidence: Full measurement logs and traceability data, and SPC are provided for peace of mind and proof for both internal QA and regulatory audits.

In one recent implementation, a leading catheter supplier reduced startup scrap by over 40% while cutting average setup time in half.

Built for Cleanroom Environments

UltraGauge+ ultrasonic is designed with the medical space in mind. The sensors are compact, IP-rated, and available in configurations suitable for:

- Cleanrooms and Class 100+ production zones

- Multi-layer extrusion with complex material transitions

- Tight-space retrofits on legacy production lines

LaserLinc’s Total Vu™ HMI platform provides intuitive real-time visualization, SPC tools, and recipe management, making adoption fast and operator-friendly.

A Strategic Advantage for MedTech Manufacturers

As the demand for smaller, smarter, and safer devices accelerates, the product size and tolerance window for medical tubing continue to shrink. Relying on outdated inspection methods introduces risk at every stage, from startup to shipment.

UltraGauge+ solutions bring precision, visibility, and confidence to every foot of tubing you produce. It’s a simple upgrade that can transform your entire extrusion process.