Posts Tagged ‘Surface Flaws’

Seeing Beyond Circularity: Detecting Shape Distortions in Continuous Casting and Rolling

Laserlinc Inc. has introduced a groundbreaking approach to shape-measurement, for continuous casting and rolling applications, enhancing precision in metal processing. Continuous Casting manufacturers rely on rolling trains—two-stage rolling systems designed to progressively reduce and shape metal into rods. The initial rough-sizing stage establishes the foundation, while the finishing stage refines the dimensions to a circular…

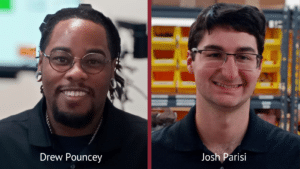

Read MoreLaserLinc Welcomes Drew Pouncey and Josh Parisi to the Technical Team

Fairborn, OH – August 31, 2023 – LaserLinc is delighted to announce the newest additions to our team: Drew Pouncey as our Technical Support Specialist and Josh Parisi as an Applications Engineer.

Read MoreLaserLinc’s FlawSense System Gains Momentum in Various Industries

Fairborn, Ohio, August 22, 2023 – LaserLinc, Inc., a leader in open, scalable measurement and process control solutions that adapt to the way you work, announced today that its FlawSense™ system, a high-speed surface defect and dimensional inspection system, has been attracting growing interest from various industries that produce or use high-value products such as wire, cable, pipe, and tube.

Read More