Operating Principle

4 YEAR WARRANTY

We’re so confident in our products that we guarantee every part we manufacture with an industry-leading four-year warranty.

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.

ETHERNET INTERFACE

These products use a standard Ethernet connection to transfer data between the device and the host processor.

POWER OVER ETHERNET (POE)

These products receive power over the same Ethernet connection used for communications, thereby eliminating the need for a separate power source, power cable, or conduit. Currently available on Axion212, Axion222, and Triton330.

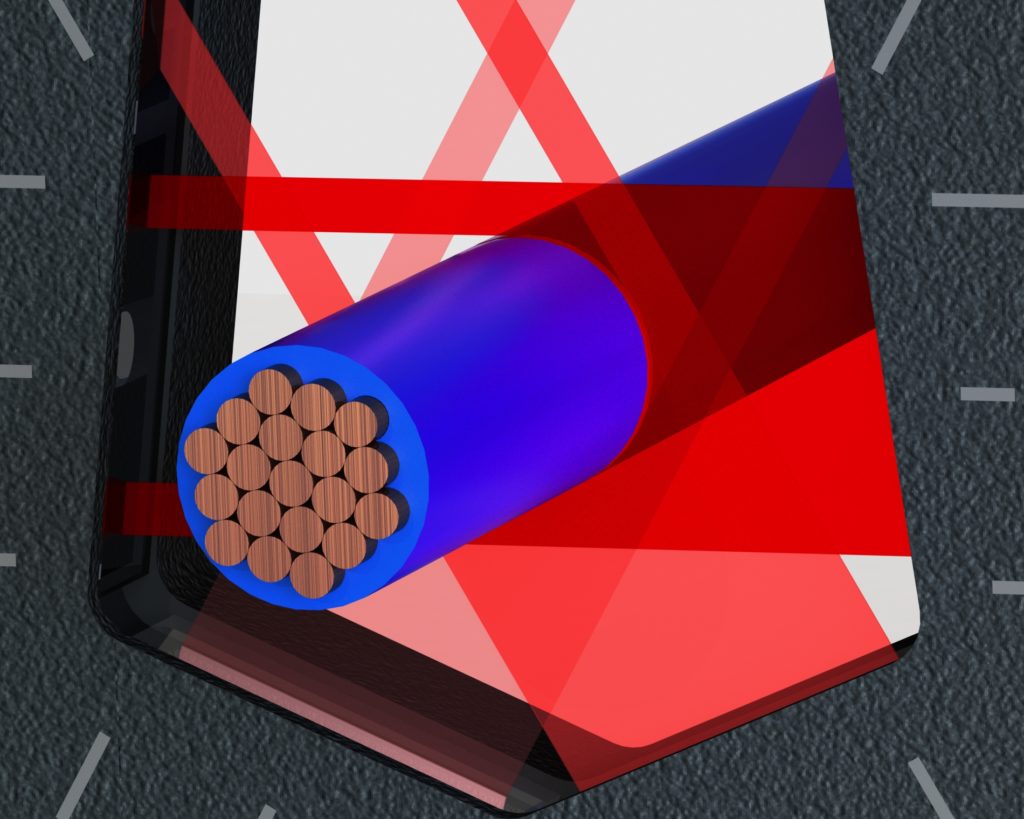

Operating Principle of Scanning Laser Micrometers

4 YEAR WARRANTY

We’re so confident in our products that we guarantee every part we manufacture with an industry-leading four-year warranty.

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.

ETHERNET INTERFACE

These products use a standard Ethernet connection to transfer data between the device and the host processor.

POWER OVER ETHERNET (POE)

These products receive power over the same Ethernet connection used for communications, thereby eliminating the need for a separate power source, power cable, or conduit. Currently available on Axion212, Axion222, and Triton330.

Laser Micrometer Operating Principle Demonstration

Check out this interactive demo to see the operating principle in action. Using your mouse, move one or more objects (black circles or squares) into the laser path. Our simulated laser measurement system will indicate the measurements between state changes of the receiver.