FlawSense Metron

Offline Non-Contact Dimensional Defect Detection

Renowned for its precision, FlawSense Metron™ Technology is ideal for inspecting parts up to 1.8 m (72 in) in length, such as catheters or medical tubes with variable diameters and tapers. Its user-friendly controls allow operators to easily load and inspect each part from the batch, ensuring the product meets specifications while identifying any surface defects.

As Easy as One. Two. Three.

1.

Place the Part

Simply place your part into the upper and lower holders to lock it into place.

2.

Run the Inspection

Start the sequence at the push of a button, and FlawSense technology will perform a 360-degree product scan to detect any surface defects.

3.

Get Results

Receive real-time results and save them as CSV files for your records.

Automated Inspection you can trust

Quickly set detection criteria

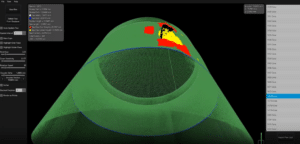

The advanced proprietary algorithms and point cloud data manipulation enable detailed contour computation. The system's high resolution and frame rate reliably detects even the smallest defects that other systems cannot. With Flaw Viewer, the defects are visualized in 3D.

Shape Error

Products are rarely a perfect circle. Vision systems and micrometers can only measure point to point, measuring only six points around the circumference for a 3-axis device. FlawSense technology measures the full 360° contour and digitizes the product in real-time, creating thousands of points. This allows FlawSense technology to eliminate dead zones and measurement uncertainty.

Laser-line Triangulation

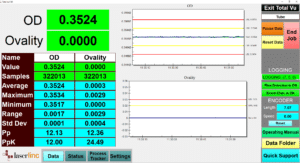

Laser-line triangulation measures diameter and ovality—providing a contour map at speeds up to 10,000 times per second and 100% inspection coverage. It accurately measures the outer diameter, ovality, and identifies defects using a true 360-degree view.

The Power of Metron Technology

LaserLinc’s non-contact measurement equipment is perfect for in-process and continuous dynamic measurements as well as manual and automated offline inspections. For cylindrical products like camshafts and catheters, checking multiple locations and dimensions is crucial for accuracy. Manual inspections are challenging due to complex profiles and the need for multiple measurement stations and skilled personnel.

With the Metron™ system, customers can anticipate shorter measurement cycle times, achieve greater value, and conduct more accurate inspections. Metron systems provide a cost-effective automated inspection solution.

The Ultimate Detection Solution

FlawSense technology precisely detects a vast

range of defects.

Detects Lumps Pits Scratches Blisters Cracks Neckdowns Streaks Wrinkles Braid Breaks

The Strength of the Platform.

The Total Vu™ HMI from LaserLinc is a comprehensive data acquisition platform for any process. It provides real-time information and enables manufacturers to aggregate, visualize, and analyze data from multiple sources. This helps detect and correct production issues, reduce waste, and improve product quality and yield.

Total Vu HMI provides:

• Access to data from anywhere in your facility with OPC UA

• Statistical process control (SPC) for insight into your process