Automated Sample Inspection

4 YEAR WARRANTY

We’re so confident in our products that we guarantee every part we manufacture with an industry-leading four-year warranty.

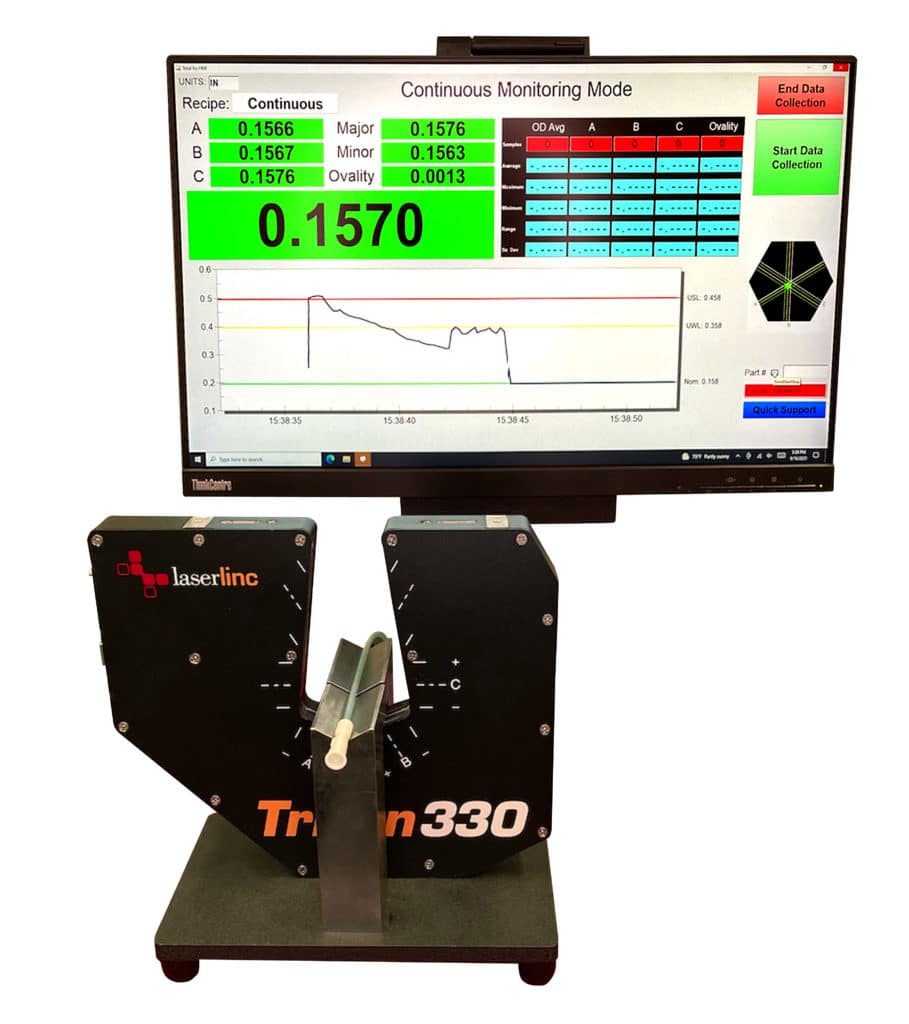

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.

Automated and Manual Sample Inspection

METRON AUTOMATED INSPECTION

Complete, accurate dimensional inspection with rapid data collection and tolerance verification. Ideal for catheters, guidewires, medical tubes, and other cylindrical products.

Metron off-line measurement for catheters, guidewires, medical tubes.

The Metron is LaserLinc’s premier off-line measurement system for long and thin parts. Metron provides complete, accurate dimensional inspection, as well as rapid data collection and tolerance verification. Outer diameter part measurement from 0.004” to 1.15” (0.10 mm to 29.2 mm).

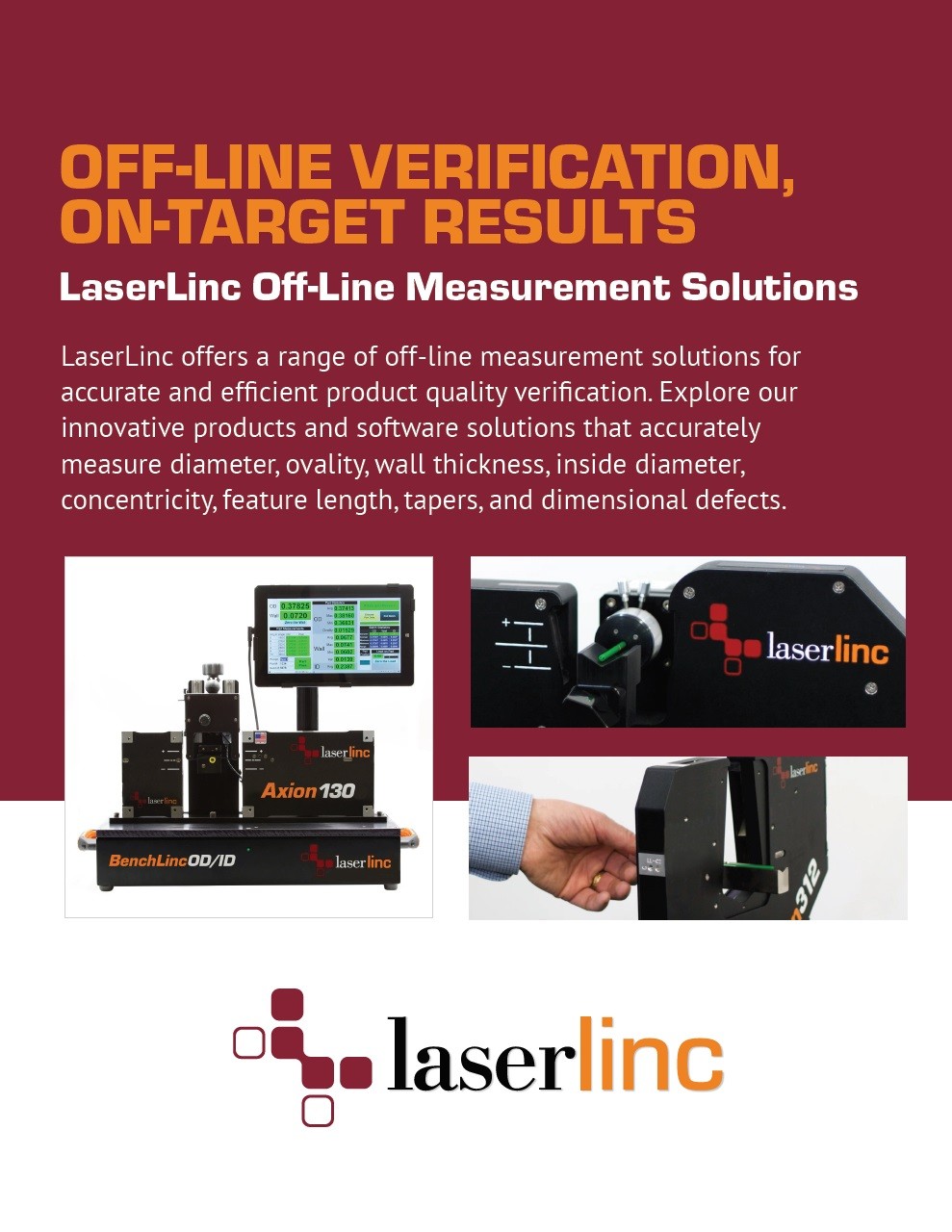

OFF-LINE VERIFICATION, ON-TARGET RESULTS

LaserLinc offers a range of off-line measurement solutions for accurate and efficient product quality verification. Explore our innovative products and software solutions that accurately measure diameter, ovality, wall thickness, inside diameter, concentricity, feature length, tapers, and dimensional defects.

Automating Dimensional Inspection Drives Considerable Efficiences

A leading medical device company needed accurate, repeatable, and reliable dimensional inspection at multiple locations on a variety of catheters. LaserLinc's Metron system offered an automated inspection solution that enhanced measurement capabilities for R&D, improved productivity, and delivered a reliable solution for production.

Closing the Loop Between In-process and Offline Measurements of Flexible Medical Tubing Products for Compliance Validation

Demand for medical device consumables, such as tubing, is increasing, creating production challenges for manufacturers. One critical challenge is how to accurately measure flexible products for compliance validation without sacrificing production speeds.

4 YEAR WARRANTY

We’re so confident in our products that we guarantee every part we manufacture with an industry-leading four-year warranty.

TOTAL VU™

These products are compatible with the Total Vu™ platform for complete product and process monitoring, reporting, and control. VIEW TOTAL VU PRODUCTS

MADE IN THE USA

We’re a 100% U.S. owned and operated company. We’re proud to design and build our products at our Fairborn, Ohio headquarters.