FlawSense™ - Experience the Paradigm Shift In Surface Flaw and Dimensional Inspection

Multi-Axis to 360° and 2D to 3D

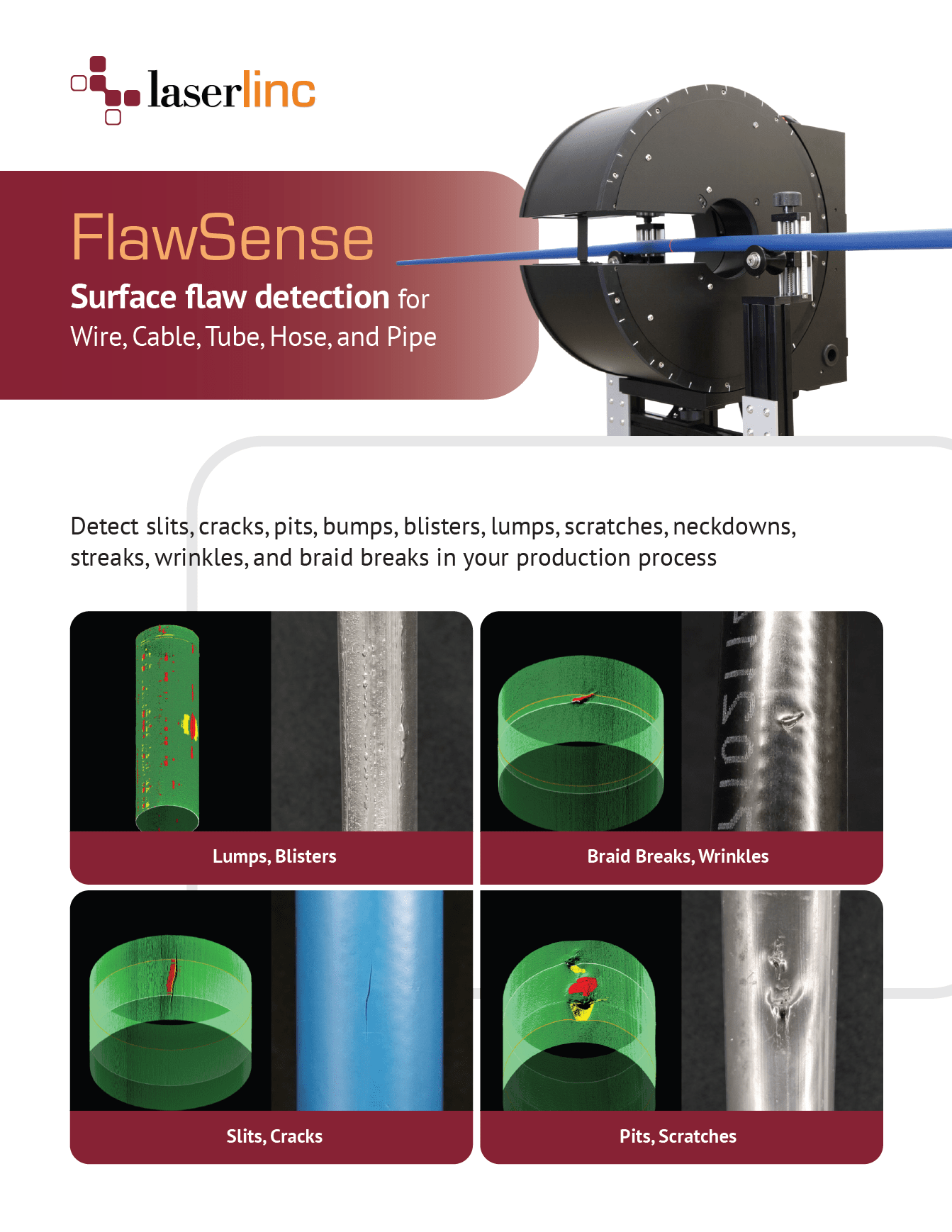

Say goodbye to unreliable vision systems, laser micrometers, lump-neckdown detectors, and manual inspection. FlawSense is the ultimate solution for surface flaw detection, and accurate and reproducible outer diameter (OD) and ovality measurements. Experience the paradigm shift with FlawSense for true 360° in-process inspection and 3D analysis...enabling you to precisely detect lumps, gels, pits, slits, and other surface defects.

Get Peace of Mind and Quality Assurance with FlawSense

FlawSense enables you to catch product defects early on, before they make their way downstream in the production process or reach your customers.

It's time to take your quality control to the next level. FlawSense automates the surface flaw detection process, providing you with a fast, accurate, and safe solution. No more human error or subjectivity - FlawSense delivers consistent, reliable results every time. Protect your products and your reputation by choosing FlawSense for your surface flaw and dimensional inspection needs. Don't settle for anything less. Contact us today!

Talk to an Application Specialist Today!

FlawSense -- Surface Flaw and Dimensional Inspection

Revolutionize your quality control process with our groundbreaking, non-contact flaw detection and dimensional inspection system.

Automating Surface Flaw Detection

Delivers Significant Value

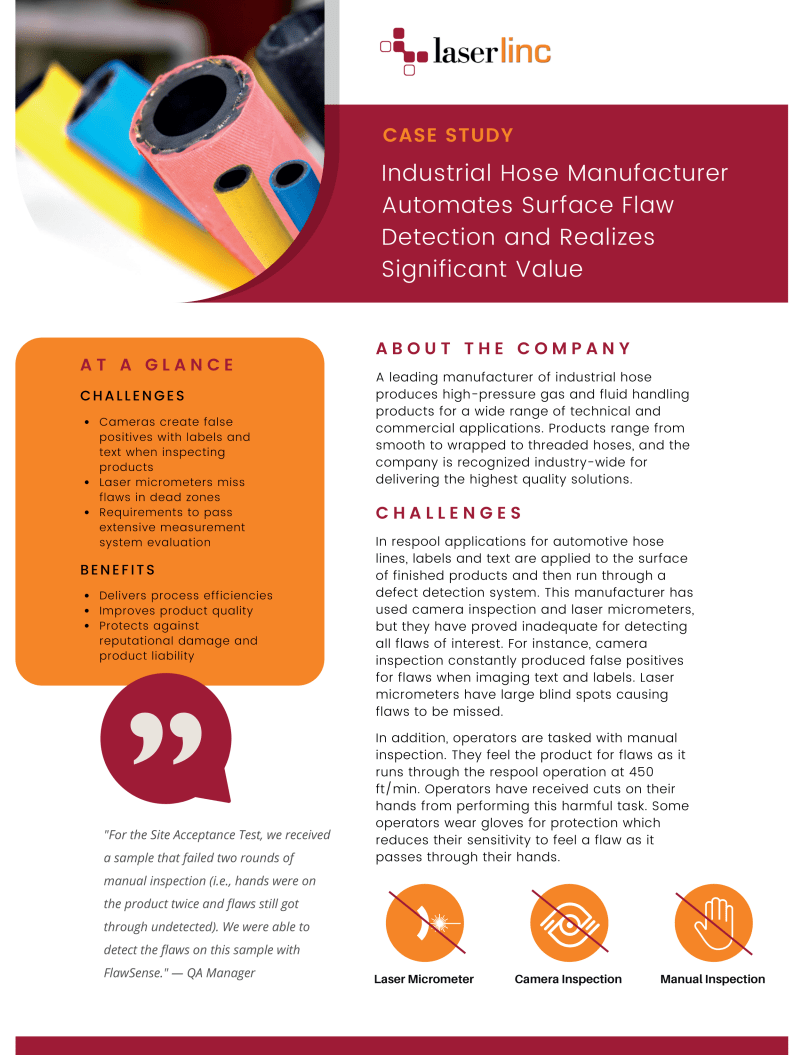

Industrial Hose Manufacturer Automates Surface Flaw Detection and Realizes Significant Value.

The company required a system to deliver accuracy better than + /-0.001 in. LaserLinc’s FlawSense surface defect detection system automated their process, delivered process efficiency, and improved product quality.

Made in the USA

LaserLinc is a U.S. company and proud to design and manufacture its products at its headquarters in Fairborn, Ohio. All LaserLinc products are backed by industry-leading service and support.