LaserLinc’s FlawSense System Gains Momentum in Various Industries

Fairborn, Ohio – LaserLinc, Inc., a leader in open, scalable measurement and process control solutions that adapt to the way you work, announced today that its FlawSense™ system, a high-speed surface defect and dimensional inspection system, has been attracting growing interest from various industries that produce or use high-value products such as wire, cable, pipe, and tube.

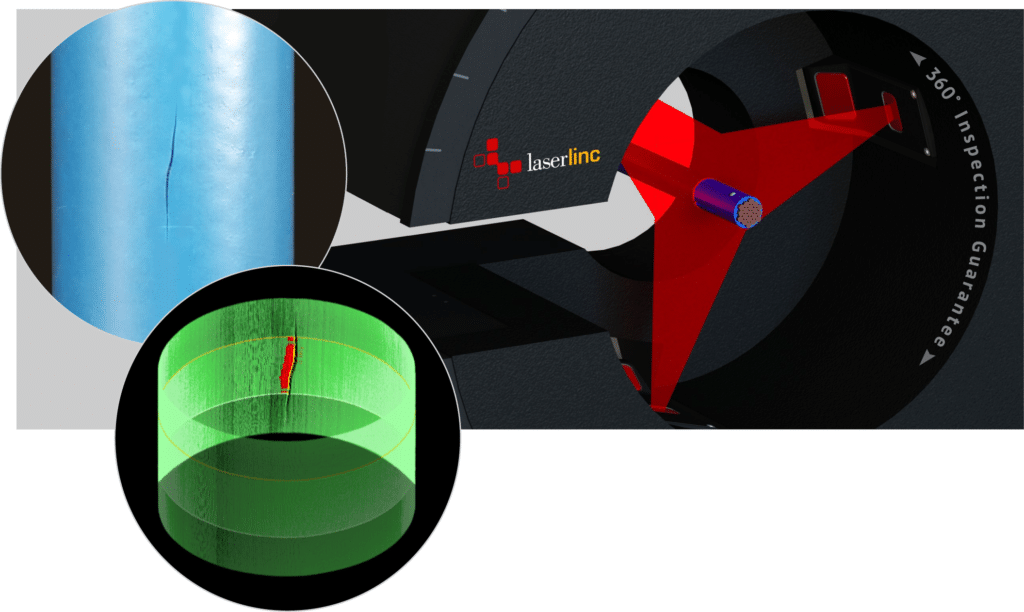

The FlawSense system is a revolutionary solution that redefines surface defect and dimensional inspection. It uses high-speed, laser-line triangulation to perform true 360° in-process inspection of cylindrical and convoluted-shaped products — regardless of product orientation in the measurement field. FlawSense can detect lumps, gels, pits, slits, and other surface defects that conventional laser micrometers and vision-based systems cannot. With FlawSense, defects can be detected in-process and reviewed later in 3D. The system also reliably measures the outer diameter and ovality of products without shape error, and provides traceability to eliminate out-of-specification items.

“We are very pleased with the positive feedback we have received from our customers and prospects who have seen the FlawSense system in action,” said Stuart Manser, Chief Revenue Officer at LaserLinc. “FlawSense is a game-changer for many industries that need to ensure the quality and integrity of their products. It can help them reduce scrap, improve yield, enhance customer satisfaction, and comply with industry standards.”

To showcase the FlawSense system and its capabilities, LaserLinc will be giving technical presentations at several upcoming exhibitions and conferences for the remainder of the year. These include:

- Graham Engineering Spotlight Conference, Sept 25-26, 2023, UMass Lowell Campus, Lowell, MA

- MD&M Minneapolis, Oct 10-11, 2023, MN, Booth 3509

- AMI Medical Tubing & Catheters, Nov 1-2, 2023, Tampa, FL

- AMI Extrusion World Expo, Nov 15-16, 2023, Cleveland, OH, Booth 1231

“We invite anyone who is interested in learning more about the FlawSense system and how it can benefit their applications to attend our presentations or visit our booths at these events,” said Manser. “We look forward to demonstrating how FlawSense can help them achieve their quality and productivity goals.”

For more information about the FlawSense system and LaserLinc’s other products and services, please visit www.laserlinc.com or contact LaserLinc at info@laserlinc.com or (937) 318-2440.